A couple of weeks ago, I noticed my Defender was not making its customary fan noise. I brought out my newish digital multi-meter, the one that sounds warning beeps then goes off after a few minutes unless you keep pressing the power button in time to keep it on, unplugged the low voltage power connector, and inserted the probes. Just a few mV, not 15 Volts AC. Defective power supply cord, again.

When not using “the clips” to press the cord down flat on the ground under the grass, the cord is vulnerable to inattentive lawn mowers. This cord had never suffered the ultimate insult, but had acquired some nicks and cuts over its 20 year life. I had repaired one nick by covering the cut insulation with liquid electrical tape. Keep out the elements, I congratulated myself at the time.

When not using “the clips” to press the cord down flat on the ground under the grass, the cord is vulnerable to inattentive lawn mowers. This cord had never suffered the ultimate insult, but had acquired some nicks and cuts over its 20 year life. I had repaired one nick by covering the cut insulation with liquid electrical tape. Keep out the elements, I congratulated myself at the time.

Taking it inside, there was no obvious damage to the cord, but it definitely didn’t work reliably. There would be moments where the indicated AC voltage would jump up when wiggling the cord, but nothing definitive. At this time, the newish multi-meter was beeping and requiring periodic attention, which led to the anxiety of not finding a problem.

I replaced the multi-meter with one of my trusty Simpson 250 analog meters. This meter can run forever with no problems of going off or needing new batteries (except for the Ohms function). Besides requiring more current from a circuit, the meter responds more quickly and precisely, and, with another pass through wiggling the 50′ low voltage cable, I found the problem in my earlier splice.

I opened the splice to find copper-colored dust where the copper wire strands once had been. The stranded wire had corroded much worse than i had ever seen. It was just incredible. I cut out the affected section and spliced the cord again. I had forgotten to add heat shrink tubing, so I had to insulate from without. Electrical tape is too bulky, unreliable, and not watertight. I didn’t want to use the liquid electrical tape because all my containers had grossly thickened, and I didn’t feel like thinning the mixture with toluene and xylene, etc., as it is a real pain to open and close the solvents, mix in a bit, shake and stir, then wait.

I remembered a substance I had discovered last year when I had problems with my above-ground pool. The top air ring was sun damaged and brittle. When the ring deflates, the pool dumps over a thousand gallons of water into the yard, which happened several times. No application of vinyl restorers could soften it. But I could repair each leak with a patch, however the supplied vinyl cement took too long to set, and didn’t last under the sun and flexing. I tried alternatives, including liquid electrical tape (which was a disaster), and finally found Shoe Goo, which is made for repairing shoes. It was handy because it works under water, seals very quickly, and seems to last pretty well in the sun.

So i tried encapsulating the splice in Shoe Goo. It is a bit tricky to work, as the substance thickens very quickly after it comes out of the tube. But in a few minutes, I had a rugged encapsulated splice!

The connector seemed intermittent. It turns out the contacts were getting old and oxidized. I somehow extracted the contacts and cleaned them, re-bent the internal springs, etc. Without a very tiny abrasive brush to fit inside the connector, I used a toothpick and some tinned hookup wire with mediocre results. Reinserting the contacts was a challenge. Nonetheless, the connectors could make a reliable connection to some tinned wire inserted to simulate the Defender’s power connector.

This was quite an effort, and I was looking forward to a successful completion. I deployed the refurbished power supply, plugged it in, and waited. Nothing. I took it out back to the bench, but all was well there. I redeployed it, and still nothing, no power. Out of time.

The unit sat like that for 2 weeks, off the air. I missed my MQTT messages, but at least I had another trap running.

Today I decided to fix the Defender. The power supply checked out OK. I opened the case (easy because long ago I took out the case screws and put them in a very safe place) and measured the AC input: Ok! But the NodeMCU had no power. A problem on the PCB assembly…

Fortunately the PCB assembly is easy to remove because of all the connectors and the AC connector mounting screws are all stripped anyway. Out it came and upstairs to the bench.

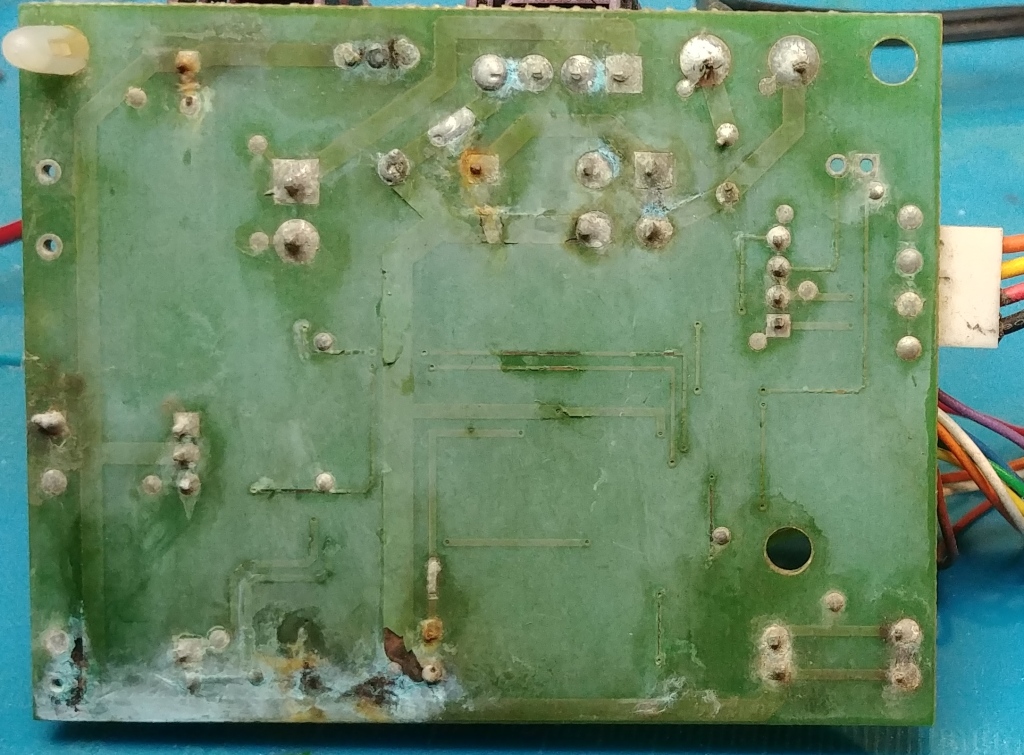

Well, isn’t that a fine looking board? Cleaning the board resulted in powdery copper coming off. The wide foil running down the left then along on the bottom horizontally is the 12 Volt rail. The thin trace from the bottom +12V running vertically 30% in from the left has a 3 mm break. There is a hole under the trace that seems to go to the +5V regulator chip on the component side. I don’t know if this is a large via for intentional contact to the chip or not. In any event, the foil was completely broken. No 12V input, yields no +5V output.

I scraped the 12V trace to expose some good copper and attached a very thin flexible wire jumper. The +5V regulator worked, and the NodeMCU signed onto the MQTT server, and sent messages.

Although in a 2013 wiki post I had mentioned not putting conformal coating on the repaired PCB, I now see the result: horrible corrosion, a natural consequence of that experiment. However, still after all these years too lazy to actually find the coating container, open it, test it, paint it on, and wait for it to cure, I started to look for something easier.

I ran across a can of flat matte spray acrylic to fix poster presentations. The can said it could be used on electrical components, and that was good enough for me (I didn’t want to add a corrosive or conductive coating, after all). Although I prefer gloss for easier inspection, this would do. So I sprayed some on the underside, dutifully turned the can upside down and cleared the nozzle, blotted the excess from the bottom edge, and wasted time until the coating was dry.

Outside, I installed the controller, powered on, and the NodeMCU came up. However, there was no fan. The unit ran for a bit, the igniter came on, the gas line solenoid opened, and I heard the pop of ignition. However, with no fan, this could not work.

This time I removed the entire so-called “power head” and brought it upstairs to the bench. While examining the unit, some disgusting looking bug scurried from the trap across the bench to start a new home in my lab. Oh, well. I wonder if I will ever find it. I re-seated the fan connector a few times, and the fan started to run. Perhaps the spray acrylic got on the contacts. Good enough for now. I took it outside, hooked it up, and it started. Hooray!

So after a silent period, the trap is again running. You can see the MQTT messages in “broker.hivemq.com” with the topic “MMD/#”. Here is the message from “MMD/esp8356707” at the time of this writing:

Temp=120.1C (-0.2) at 5:11711 F=1 I=0 G=1 S=1 E=0 T=28.5C H=57.3% M=26728 (247/1024:5984) R=70~140 W=-74.85 B=0.0 V=3.5

The combustion temperature rise is about 92°C above ambient, typical.

I should mention that looking at the Shoe Goo encapsulated splice, I noticed a greenish spot, which is not encouraging. I may have to revisit this splice. Stay tuned.