Home

>

Mosquito Magnet

>

Topic

2011 Executive pcb outputting ~halved voltages to fan+solenoid

Posted by iikkakonola

|

2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 06:56AM | Registered: 2 years ago Posts: 10 |

Hi. I have a 2011 model of Mosquito Magnet executive.

Device is powered with a 4.8V NiMh cell (that is brand new, confirmed working) for initial startup, and a thermoelectric module(peltier?) that generates current after device has reached working temperature. Unit has following order from start to "running" status:

-12V 0.4A (PWM controlled 3-lead (white,red,black)) 120mm fan starts to run in about 40% speed-at ~20sec mark an igniter circuit starts to fire twice a second inside the combustion chamber

-at ~25sec mark an 12V DC solenoid actuates a gas valve that starts to emit gas inside combustion chamber that has a 188kOhm thermistor- once 188kOhm thermistor is at certain resistance level(device has heated up enough) the 12V fan starts to run at 100% speed and device sets it's status as "running" (status led and lcd screen shows running etc)

-once voltage from thermoelectric module is higher than voltage from battery pack, unit switches a relay that was initially supplying power from battery pack to TEM.

My unit has following problem - when 12V solenoid should actuate, only a 4,98V voltage is found on it's connecting pins. This is not enough for solenoid to actuate. I confirmed from official repair tech that normal working unit has 10V voltage at this point. This can be "fixed" with a boost converter that steps up the voltage from 5V to 10V and that actually works, gas comes on and flame ignites.

With the boost module, other problem is with 12V fan - it starts to "run" with 2.3V voltage, with really low rpm.

I haven't been able to confirm the correct voltage from a working unit(i surmise it should be 2.3V x 2 = 4.6V). When the fan only works with (supposedly) half voltage, it maybe causes overheating/too low flow of heat to to thermistor and low/high thermistor readings cause unit to shut off eventually.

Unit has following notable IC:s, with data sheet links:

76650 8BT LOW DROPOUT VOLTAGE REGULATOR

https://www.ti.com/lit/ds/symlink/tps766.pdf?ts=1627365910316

431AC Programmable Voltage Reference

https://pdf1.alldatasheet.com/datasheet-pdf/view/197558/STMICROELECTRONICS/431AC.html

2700MT 2.5A Step-up PWM DC/DC Converter

https://www.ti.com/lit/gpn/lm2700

pin2 feedback resistors (6.8Kohm1.02Kohm

pictures to PCB and IC:s

https://imgur.com/a/62CdVmT

My best guess is that 2700MT has crapped out someway and is only outputting "halved" voltages.I am very talented at searching for problems at wrong places and decided that it is time for me to even try to ask someone with some real talent for help, as i really would like to get this unit up and running.

Nothing pops up on FLIR IR camera, only SS22 schottky diode shows up with 50C' / 122f temps.

My attempt at using a boost converter worked with solenoid, i don't think it adds to problems with increased conversion losses, my bench supply showed 0.19A draw with 5V when boost module upped the voltage to 10V.

problem with fan could be MAYBE remedied with a module that effectively doubles the input voltage that it receives - the fan is supplied normally with alternating voltages so a one-off boost module would not work here. I suspect the fan to be a pwm controlled one, but if there is only 2.3V voltage coming in i also suspect it is a voltage controlled unit..

My "attempts" are consequence of lack of a reflow station, right replacement IC:s and maybe battle fatigue.

best regards from Finland.

ps. i have been in awe of this forum! I use wemos d1 mini's in my home automation, using mqtt for home assistant. I would be really interested in throwing away all the crappy design pcb:s from my mm:s and replace those with open source pcb:s.. : )

Device is powered with a 4.8V NiMh cell (that is brand new, confirmed working) for initial startup, and a thermoelectric module(peltier?) that generates current after device has reached working temperature. Unit has following order from start to "running" status:

-12V 0.4A (PWM controlled 3-lead (white,red,black)) 120mm fan starts to run in about 40% speed-at ~20sec mark an igniter circuit starts to fire twice a second inside the combustion chamber

-at ~25sec mark an 12V DC solenoid actuates a gas valve that starts to emit gas inside combustion chamber that has a 188kOhm thermistor- once 188kOhm thermistor is at certain resistance level(device has heated up enough) the 12V fan starts to run at 100% speed and device sets it's status as "running" (status led and lcd screen shows running etc)

-once voltage from thermoelectric module is higher than voltage from battery pack, unit switches a relay that was initially supplying power from battery pack to TEM.

My unit has following problem - when 12V solenoid should actuate, only a 4,98V voltage is found on it's connecting pins. This is not enough for solenoid to actuate. I confirmed from official repair tech that normal working unit has 10V voltage at this point. This can be "fixed" with a boost converter that steps up the voltage from 5V to 10V and that actually works, gas comes on and flame ignites.

With the boost module, other problem is with 12V fan - it starts to "run" with 2.3V voltage, with really low rpm.

I haven't been able to confirm the correct voltage from a working unit(i surmise it should be 2.3V x 2 = 4.6V). When the fan only works with (supposedly) half voltage, it maybe causes overheating/too low flow of heat to to thermistor and low/high thermistor readings cause unit to shut off eventually.

Unit has following notable IC:s, with data sheet links:

76650 8BT LOW DROPOUT VOLTAGE REGULATOR

https://www.ti.com/lit/ds/symlink/tps766.pdf?ts=1627365910316

431AC Programmable Voltage Reference

https://pdf1.alldatasheet.com/datasheet-pdf/view/197558/STMICROELECTRONICS/431AC.html

2700MT 2.5A Step-up PWM DC/DC Converter

https://www.ti.com/lit/gpn/lm2700

pin2 feedback resistors (6.8Kohm1.02Kohm

pictures to PCB and IC:s

https://imgur.com/a/62CdVmT

My best guess is that 2700MT has crapped out someway and is only outputting "halved" voltages.I am very talented at searching for problems at wrong places and decided that it is time for me to even try to ask someone with some real talent for help, as i really would like to get this unit up and running.

Nothing pops up on FLIR IR camera, only SS22 schottky diode shows up with 50C' / 122f temps.

My attempt at using a boost converter worked with solenoid, i don't think it adds to problems with increased conversion losses, my bench supply showed 0.19A draw with 5V when boost module upped the voltage to 10V.

problem with fan could be MAYBE remedied with a module that effectively doubles the input voltage that it receives - the fan is supplied normally with alternating voltages so a one-off boost module would not work here. I suspect the fan to be a pwm controlled one, but if there is only 2.3V voltage coming in i also suspect it is a voltage controlled unit..

My "attempts" are consequence of lack of a reflow station, right replacement IC:s and maybe battle fatigue.

best regards from Finland.

ps. i have been in awe of this forum! I use wemos d1 mini's in my home automation, using mqtt for home assistant. I would be really interested in throwing away all the crappy design pcb:s from my mm:s and replace those with open source pcb:s.. : )

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 02:37PM | Registered: 3 years ago Posts: 152 |

Welcome! It's nice to see an Executive MM show up, from Finland no less!

From your description, it would appear (as I expected) that the fundamental design and operation of the Executive is the same as the Liberty Plus and Independence models, with the exception of the larger processor and LCD display. For reference, here is the schematic of the Independence

If the Executive is the same, both the fan and solenoid are driven from the boosted voltage, which is about 9.7v on my units. So your symptoms certainly sound like the boost converter is not working. The older units use a LM2577 while your uses a LM2700, which has a higher frequency and is more efficient, but essentially does the same thing. Looks like you have to check out the boost converter circuit for proper operation. You should also check out the microprocessor output pin to turn on the boost converter. You don't need a reflow station to work these boards, just a fine tipped soldering iron, some Chip Quick low melt solder, and maybe a cheap digital microscope. I don't know about the parts supply in Finland, but all the parts are pretty common and shouldn't be hard to find.

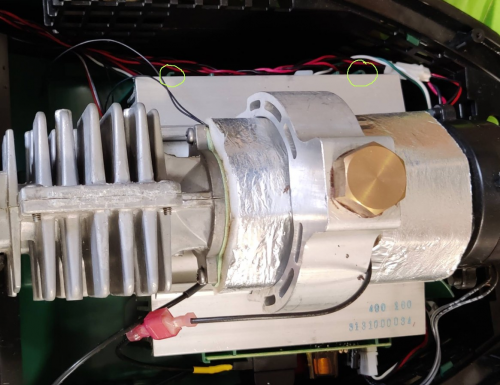

Thanks for the picture of the Executive board. It looks like they changed the location of the circuit board. On the Independence, it's a rectangular board to one side of the unit, but it looks like this board sits just under the front panel. The board is also curved, which makes it a bit harder and more expensive to fabricate.

From your description, it would appear (as I expected) that the fundamental design and operation of the Executive is the same as the Liberty Plus and Independence models, with the exception of the larger processor and LCD display. For reference, here is the schematic of the Independence

If the Executive is the same, both the fan and solenoid are driven from the boosted voltage, which is about 9.7v on my units. So your symptoms certainly sound like the boost converter is not working. The older units use a LM2577 while your uses a LM2700, which has a higher frequency and is more efficient, but essentially does the same thing. Looks like you have to check out the boost converter circuit for proper operation. You should also check out the microprocessor output pin to turn on the boost converter. You don't need a reflow station to work these boards, just a fine tipped soldering iron, some Chip Quick low melt solder, and maybe a cheap digital microscope. I don't know about the parts supply in Finland, but all the parts are pretty common and shouldn't be hard to find.

Thanks for the picture of the Executive board. It looks like they changed the location of the circuit board. On the Independence, it's a rectangular board to one side of the unit, but it looks like this board sits just under the front panel. The board is also curved, which makes it a bit harder and more expensive to fabricate.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 02:45PM | Registered: 3 years ago Posts: 152 |

iikkakonola wrote:

My "attempts" are consequence of lack of a reflow station, right replacement IC:s and maybe battle fatigue.

As far as replacement ICs, it seems Mouser has a Finnish site, although the prices and shipping charges are considerably more than in the US, since they probably ship from the US. But it's free shipping if you spend more than 50 euros. And at least you can get the components....

Edited 2 time(s). Last edit at 08/19/2021 02:51PM by Independence.

My "attempts" are consequence of lack of a reflow station, right replacement IC:s and maybe battle fatigue.

As far as replacement ICs, it seems Mouser has a Finnish site, although the prices and shipping charges are considerably more than in the US, since they probably ship from the US. But it's free shipping if you spend more than 50 euros. And at least you can get the components....

Edited 2 time(s). Last edit at 08/19/2021 02:51PM by Independence.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 03:02PM | Registered: 2 years ago Posts: 10 |

Thank you for fast response!

I have already ordered the LM-2700 in MT packaging, it is arriving from China "sometime" this autumn probably.

Also ordered a 858D hot air station as this is not the first rodeo for me, when I would needed such thing.

By no means I have same level of expertise that people here have, but it seems I predicted the same point of failure!

I have already ordered the LM-2700 in MT packaging, it is arriving from China "sometime" this autumn probably.

Also ordered a 858D hot air station as this is not the first rodeo for me, when I would needed such thing.

By no means I have same level of expertise that people here have, but it seems I predicted the same point of failure!

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 03:20PM | Registered: 3 years ago Posts: 152 |

iikkakonola wrote:

it is arriving from China "sometime" this autumn probably.

Ha ha, I guess we take fast delivery for granted here in the US. For me, anything other than 2-4 days delivery would be too long! :)

A hot air station is a useful tool to have, but I would suggest you also invest in some low melt solder. It is MUCH easier to remove SMD parts with this solder and you are also less likely to damage any parts or the board as you don't need to heat it up that much. Even when I use my hot air station, I lay down some low melt solder with an iron first, and then just a bit of hot air is enough to release the part.

it is arriving from China "sometime" this autumn probably.

Ha ha, I guess we take fast delivery for granted here in the US. For me, anything other than 2-4 days delivery would be too long! :)

A hot air station is a useful tool to have, but I would suggest you also invest in some low melt solder. It is MUCH easier to remove SMD parts with this solder and you are also less likely to damage any parts or the board as you don't need to heat it up that much. Even when I use my hot air station, I lay down some low melt solder with an iron first, and then just a bit of hot air is enough to release the part.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 03:22PM | Registered: 3 years ago Posts: 152 |

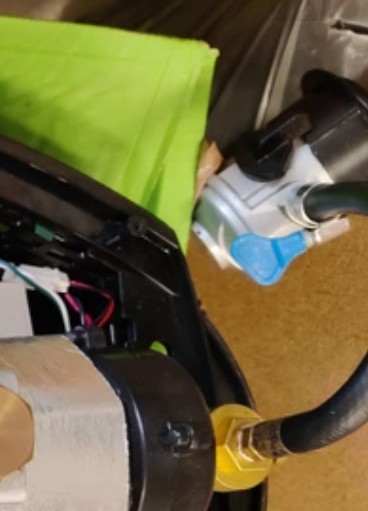

BTW, I'm curious about the internal layout of the Executive. If you don't mind taking some pictures of the internal layout and posting them here, I'd appreciate it. They occasionally show up used for cheap and I was considering getting one and re-spinning my board for it, minus the display, since my version is web enabled anyway.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 19, 2021 04:31PM | Registered: 2 years ago Posts: 10 |

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 20, 2021 05:40AM | Registered: 2 years ago Posts: 10 |

uh-kay, i managed to make time this morning(GMT+2) and take some photos on oneplus 8t..

https://imgur.com/a/prwG2xN

The photos are blurry on the edges, probably the camera is optimized for wide angle photos. I can take better shots per request if someone wants.

Here is a picture i received from the official MM importer, saying that the spare parts they can provide for executive are of newer pcb revision:

https://imgur.com/a/1Hjz1ye

Notable differences are ambient temp thermistor and connectors for the power connection etc.--> no need to desolder everything for a board swap. Tells a tale that there has been need for board swaps...eh?

Edited 1 time(s). Last edit at 08/20/2021 05:44AM by iikkakonola.

https://imgur.com/a/prwG2xN

The photos are blurry on the edges, probably the camera is optimized for wide angle photos. I can take better shots per request if someone wants.

Here is a picture i received from the official MM importer, saying that the spare parts they can provide for executive are of newer pcb revision:

https://imgur.com/a/1Hjz1ye

Notable differences are ambient temp thermistor and connectors for the power connection etc.--> no need to desolder everything for a board swap. Tells a tale that there has been need for board swaps...eh?

Edited 1 time(s). Last edit at 08/20/2021 05:44AM by iikkakonola.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 20, 2021 01:44PM | Registered: 3 years ago Posts: 152 |

Oh sorry, I meant mechanical pictures of the insides of the MM, not more detailed pictures of the main board. Kinda like the first and third pictures in this post.

My goal is to see if the inside mechanical layout is still the same and the slots for the old board and the ignitor board are still there.

Next time I modify my Independence board, I will convert it to the LM2700 part. It's more efficient than the LM2577 part and uses a much smaller inductor than the large one previously used.

My goal is to see if the inside mechanical layout is still the same and the slots for the old board and the ignitor board are still there.

Next time I modify my Independence board, I will convert it to the LM2700 part. It's more efficient than the LM2577 part and uses a much smaller inductor than the large one previously used.

|

Executive ~halved voltages to fan+solenoid August 20, 2021 10:29PM | Admin Registered: 7 years ago Posts: 164 |

Referencing the Independence schematic (I hope similar to the Executive):

My unit has following problem - when 12V solenoid should actuate, only a 4,98V voltage is found...

This can be "fixed" with a boost converter that steps up the voltage from 5V to 10V...

Did you measure the 2700MT output voltage after the diode and across the output caps? How does this compare to the input voltage to the chip and inductor? Is the output voltage higher, or lower?

With the boost module, other problem is with 12V fan - it starts to "run" with 2.3V voltage, with really low rpm.

Is the 12v fan connected to the 10 volts from the 5-10 volt boost converter, or is it running on ~5v from the 2700MT circuit? (I don't understand where the 2.3 volts is coming from.)

My best guess is that 2700MT has crapped out someway and is only outputting "halved" voltages. ... Nothing pops up on FLIR IR camera, only SS22 schottky diode shows up with 50C' / 122f temps.

That chip is not smart enough to output halved voltages. Its output FET just switches, or goes open circuit. The output voltage divided by the pin2 resistors compared to 1.26 volts determines the switching duty cycle. Also, why would the schottky be hot? Excessive reverse leakage?

You may have to consider excessive current draw on the output. Disconnect the fan, etc. Any change?

Do you have (or can borrow) an oscilloscope to look at the waveforms before and after the schottky diode? Is it switching? If so, what frequency? If no scope, can you put a VOM on the switch pin and measure an AC waveform? If there is none, the unit is not switching. Is the diode shorted? This would cause excessive current in the FET, its temperature would rise, and it would shut down, cycling as it cooled, or perhaps it would shut off after a very brief time because of excessive current. These ICs can tolerate a fair amount of fault conditions, they are supposed to be protected from this and that.

How about the other pins, for example the /shdn pin? It should be at a logic high (or perhaps open). (What I don't understand about this circuit is the purpose of the shutdown function, which cannot reduce the output voltage to zero because of the DC path through the inductor and diode.) Otherwise the output voltage will be the same as the input less the schottky voltage drop.

pin2 feedback resistors (6.8Kohm 1.02Kohm)

1.26v/1020 ohms = 0.0012 A * 6800 ohms = 8.16v + 1.26v = 9.42 volts nominal output. Did you measure the resistor values, checking for contamination that might "short out" the 6800 ohm divider resistor?

Perhaps that 5V to 10V boost converter could replace your 2700MT circuit if all else fails, or you are in a hurry.

My unit has following problem - when 12V solenoid should actuate, only a 4,98V voltage is found...

This can be "fixed" with a boost converter that steps up the voltage from 5V to 10V...

Did you measure the 2700MT output voltage after the diode and across the output caps? How does this compare to the input voltage to the chip and inductor? Is the output voltage higher, or lower?

With the boost module, other problem is with 12V fan - it starts to "run" with 2.3V voltage, with really low rpm.

Is the 12v fan connected to the 10 volts from the 5-10 volt boost converter, or is it running on ~5v from the 2700MT circuit? (I don't understand where the 2.3 volts is coming from.)

My best guess is that 2700MT has crapped out someway and is only outputting "halved" voltages. ... Nothing pops up on FLIR IR camera, only SS22 schottky diode shows up with 50C' / 122f temps.

That chip is not smart enough to output halved voltages. Its output FET just switches, or goes open circuit. The output voltage divided by the pin2 resistors compared to 1.26 volts determines the switching duty cycle. Also, why would the schottky be hot? Excessive reverse leakage?

You may have to consider excessive current draw on the output. Disconnect the fan, etc. Any change?

Do you have (or can borrow) an oscilloscope to look at the waveforms before and after the schottky diode? Is it switching? If so, what frequency? If no scope, can you put a VOM on the switch pin and measure an AC waveform? If there is none, the unit is not switching. Is the diode shorted? This would cause excessive current in the FET, its temperature would rise, and it would shut down, cycling as it cooled, or perhaps it would shut off after a very brief time because of excessive current. These ICs can tolerate a fair amount of fault conditions, they are supposed to be protected from this and that.

How about the other pins, for example the /shdn pin? It should be at a logic high (or perhaps open). (What I don't understand about this circuit is the purpose of the shutdown function, which cannot reduce the output voltage to zero because of the DC path through the inductor and diode.) Otherwise the output voltage will be the same as the input less the schottky voltage drop.

pin2 feedback resistors (6.8Kohm 1.02Kohm)

1.26v/1020 ohms = 0.0012 A * 6800 ohms = 8.16v + 1.26v = 9.42 volts nominal output. Did you measure the resistor values, checking for contamination that might "short out" the 6800 ohm divider resistor?

Perhaps that 5V to 10V boost converter could replace your 2700MT circuit if all else fails, or you are in a hurry.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 21, 2021 03:13AM | Registered: 3 years ago Posts: 152 |

dev wrote:

What I don't understand about this circuit is the purpose of the shutdown function, which cannot reduce the output voltage to zero because of the DC path through the inductor and diode.

I believe they shut down the switcher to save battery power when the unit is in the 'off' state. These units are never really off and the off function just puts the processor in a hibernate state. They won't want the switcher to be running in that state.

(I don't understand where the 2.3 volts is coming from.)

Most likely he is measuring the fan voltage with a DC volt meter and that is the average reading it is giving for a 40% duty cycle 5V PWM signal.

Edited 1 time(s). Last edit at 08/21/2021 03:17AM by Independence.

What I don't understand about this circuit is the purpose of the shutdown function, which cannot reduce the output voltage to zero because of the DC path through the inductor and diode.

I believe they shut down the switcher to save battery power when the unit is in the 'off' state. These units are never really off and the off function just puts the processor in a hibernate state. They won't want the switcher to be running in that state.

(I don't understand where the 2.3 volts is coming from.)

Most likely he is measuring the fan voltage with a DC volt meter and that is the average reading it is giving for a 40% duty cycle 5V PWM signal.

Edited 1 time(s). Last edit at 08/21/2021 03:17AM by Independence.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 22, 2021 03:29PM | Registered: 2 years ago Posts: 10 |

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 22, 2021 05:28PM | Registered: 3 years ago Posts: 152 |

Thank you for the photos. The innards certainly look identical to the Independence model. From one of the photos, it looks like the mounting tabs for the old board still exits - see yellow circles:

The only thing I am not totally clear about is how the current board is mounted. It appears to located at the top where the old handle was. I presume it mounts to the top, covering the hole where the handle is, and has a top cover that snaps on. Can you confirm?

Also, it's interesting to see how different your propane gas regulator is from our common US versions.

The only thing I am not totally clear about is how the current board is mounted. It appears to located at the top where the old handle was. I presume it mounts to the top, covering the hole where the handle is, and has a top cover that snaps on. Can you confirm?

Also, it's interesting to see how different your propane gas regulator is from our common US versions.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 22, 2021 05:58PM | Registered: 2 years ago Posts: 10 |

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 26, 2021 08:11PM | Admin Registered: 7 years ago Posts: 164 |

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid August 26, 2021 08:13PM | Registered: 2 years ago Posts: 10 |

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 03, 2021 11:10AM | Registered: 2 years ago Posts: 10 |

bit of an update - my reflow station and spare IC :s came.

I have to say that it is really darn hard to try to replace the ic:s. I managed to pull off 2(!) of the pcb connecting terminals when removing the old ic, used too much power and practiced too little before attempting that...

Is there any way to replace the leads where IC:s sit on? I am starting to think this is a dead pcb, unless there is a way to make the ic sit on "air" with really thin leads going into the pcb terminals... :(

I have to say that it is really darn hard to try to replace the ic:s. I managed to pull off 2(!) of the pcb connecting terminals when removing the old ic, used too much power and practiced too little before attempting that...

Is there any way to replace the leads where IC:s sit on? I am starting to think this is a dead pcb, unless there is a way to make the ic sit on "air" with really thin leads going into the pcb terminals... :(

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 03, 2021 02:43PM | Registered: 3 years ago Posts: 152 |

iikkakonola wrote:

I have to say that it is really darn hard to try to replace the ic:s.

As mentioned earlier:

A hot air station is a useful tool to have, but I would suggest you also invest in some low melt solder. It is MUCH easier to remove SMD parts with this solder and you are also less likely to damage any parts or the board as you don't need to heat it up that much.

I didn't suggest the above lightly, it is based on experience :). You also didn't mention whether you used any flux during the removal, which you also need.

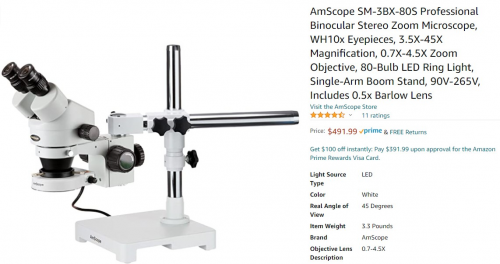

At this point, you are into SMD board repair and with that size device, you definitely need a microscope. Ideally, you'd want a stereo zoom microscope like this:

But those are pricey and unless you are going to be doing a lot of work with it, it's hard to justify. Digital scopes like the one below are a less expensive but still viable solution. Don't go for too much magnification, you really only need like 7X to 10X for most work:

Along with the microscope, you also need a pair of fine tweezers, xacto knife, flux, solder wick, and a fine tip soldering iron. After fluxing and wicking off the remaining IC pads, place the new IC in place with flux, and lightly touch the soldering iron to one pad to attach it. Once you have soldered the other pads, you can begin the repair work. There is no need to hot air flow these devices to the board. Much easier and safer to use a fine tip iron with flux. To repair the traces, you will need some fine wire. I usually get these from fine multi-stranded wire. Just strip the wire and use one strand from it. On the board, you want to use the xacto knife to cut off the lifted trace, and then use the knife remove the solder mask from the end of the remaining trace. Then you can attach the fine wire to the trace and run it to the pin on the IC. All this will be done using the microscope as it's too small to do it without it.

At this point, since your board is already damaged, you have nothing to loose by trying to repair it. It is only a double sided board, so it is eminently repairable, compared to a 4 or higher layer board.

Edit:

This youtube video shows what you have to do.

Edited 1 time(s). Last edit at 09/03/2021 02:48PM by Independence.

I have to say that it is really darn hard to try to replace the ic:s.

As mentioned earlier:

A hot air station is a useful tool to have, but I would suggest you also invest in some low melt solder. It is MUCH easier to remove SMD parts with this solder and you are also less likely to damage any parts or the board as you don't need to heat it up that much.

I didn't suggest the above lightly, it is based on experience :). You also didn't mention whether you used any flux during the removal, which you also need.

At this point, you are into SMD board repair and with that size device, you definitely need a microscope. Ideally, you'd want a stereo zoom microscope like this:

But those are pricey and unless you are going to be doing a lot of work with it, it's hard to justify. Digital scopes like the one below are a less expensive but still viable solution. Don't go for too much magnification, you really only need like 7X to 10X for most work:

Along with the microscope, you also need a pair of fine tweezers, xacto knife, flux, solder wick, and a fine tip soldering iron. After fluxing and wicking off the remaining IC pads, place the new IC in place with flux, and lightly touch the soldering iron to one pad to attach it. Once you have soldered the other pads, you can begin the repair work. There is no need to hot air flow these devices to the board. Much easier and safer to use a fine tip iron with flux. To repair the traces, you will need some fine wire. I usually get these from fine multi-stranded wire. Just strip the wire and use one strand from it. On the board, you want to use the xacto knife to cut off the lifted trace, and then use the knife remove the solder mask from the end of the remaining trace. Then you can attach the fine wire to the trace and run it to the pin on the IC. All this will be done using the microscope as it's too small to do it without it.

At this point, since your board is already damaged, you have nothing to loose by trying to repair it. It is only a double sided board, so it is eminently repairable, compared to a 4 or higher layer board.

Edit:

This youtube video shows what you have to do.

Edited 1 time(s). Last edit at 09/03/2021 02:48PM by Independence.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 03, 2021 02:58PM | Registered: 2 years ago Posts: 10 |

Thanks for the elaborate post.

I used "amtech" solder, a Chinese knock off that works quite well.

I used too much hot air flow, solder ok pcb did not even try to melt under 400C temperature, that sounds cracy high to me. IC:s have super low time that they survive under that temp I think.

I have a spare 2700MT, I have to fix the pads first when I have the time... And good mental health status :-)

I used "amtech" solder, a Chinese knock off that works quite well.

I used too much hot air flow, solder ok pcb did not even try to melt under 400C temperature, that sounds cracy high to me. IC:s have super low time that they survive under that temp I think.

I have a spare 2700MT, I have to fix the pads first when I have the time... And good mental health status :-)

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 03, 2021 03:19PM | Registered: 3 years ago Posts: 152 |

iikkakonola wrote:

I used "amtech" solder, a Chinese knock off that works quite well.

They don't make the special low melting point solder I'm talking about. The Chip Quick solder melts at about 85C and is designed specifically for removing SMD devices. Take my word for it and avoid the heartache. Check out the video on their website.

I used "amtech" solder, a Chinese knock off that works quite well.

They don't make the special low melting point solder I'm talking about. The Chip Quick solder melts at about 85C and is designed specifically for removing SMD devices. Take my word for it and avoid the heartache. Check out the video on their website.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 03, 2021 05:25PM | Admin Registered: 7 years ago Posts: 164 |

... pcb did not even try to melt under 400C temperature...

Regarding the 400°C hot air failing to unsolder the chip, did you first remove the conformal coating and flux the pins? You should have observed the existing solder melt and re-flow. After some experimentation, I now use about 350°C.

The Chip Quick solder melts at about 85C and is designed specifically for removing SMD devices.

What a great idea! Before I got a hot air station, I used flux, fine solder wick, then an insulin syringe to barely pry off each lead, a very time consuming and difficult process. Patience was key. I never tried it without a ~20-50x stereo microscope, however. Nowadays, I just apply a lot of flux, heat the chip until it starts to re-flow, slide it a tiny bit to make sure, then carefully pry up one edge using the syringe and flip it off. But using this low melting point fusible alloy seems to make it so much easier and safer for the board.

As mentioned in a previous reply, you can definitely repair the lifted foils using very fine wire from a length of stranded wire. The wire must be much more flexible than the foils to avoid lifting additional lengths of trace. I agree that you should use a microscope. This will be important for inspecting the soldering to your newly soldered chip as well.

I would like to try one of the digital microscopes you suggested. One would think they "must" have improved to the point where are useful for SMD by now.

Edited 1 time(s). Last edit at 09/03/2021 05:39PM by dev.

Regarding the 400°C hot air failing to unsolder the chip, did you first remove the conformal coating and flux the pins? You should have observed the existing solder melt and re-flow. After some experimentation, I now use about 350°C.

The Chip Quick solder melts at about 85C and is designed specifically for removing SMD devices.

What a great idea! Before I got a hot air station, I used flux, fine solder wick, then an insulin syringe to barely pry off each lead, a very time consuming and difficult process. Patience was key. I never tried it without a ~20-50x stereo microscope, however. Nowadays, I just apply a lot of flux, heat the chip until it starts to re-flow, slide it a tiny bit to make sure, then carefully pry up one edge using the syringe and flip it off. But using this low melting point fusible alloy seems to make it so much easier and safer for the board.

As mentioned in a previous reply, you can definitely repair the lifted foils using very fine wire from a length of stranded wire. The wire must be much more flexible than the foils to avoid lifting additional lengths of trace. I agree that you should use a microscope. This will be important for inspecting the soldering to your newly soldered chip as well.

I would like to try one of the digital microscopes you suggested. One would think they "must" have improved to the point where are useful for SMD by now.

Edited 1 time(s). Last edit at 09/03/2021 05:39PM by dev.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 03, 2021 11:36PM | Registered: 3 years ago Posts: 152 |

dev wrote:

What a great idea! (Chip Quik)

No kidding! Once you start using it, you will not go back. A hot air station is needed for many devices like BGAs, etc, but for leaded SMD devices, Chip Quik is a much better solution for folks like us who don't do it for a living. The hot air station temperature can vary tremendously based on the distance from the board, so unless you do it everyday and have a good feel for it, it is very easy to overheat the device and board.

I would like to try one of the digital microscopes you suggested. One would think they "must" have improved to the point where are useful for SMD by now.

I don't have one myself, but they are certainly inexpensive enough to try. I am kinda used to the stereo image and variable optical zoom of my scope but if I didn't have it, I would consider the digital solution. Looking at a monitor while re-working is slightly different from peering through the eyepieces, but I'm sure you can get used to it. My scope doesn't have a camera prism so the digital version would make it easier to capture an image.

What a great idea! (Chip Quik)

No kidding! Once you start using it, you will not go back. A hot air station is needed for many devices like BGAs, etc, but for leaded SMD devices, Chip Quik is a much better solution for folks like us who don't do it for a living. The hot air station temperature can vary tremendously based on the distance from the board, so unless you do it everyday and have a good feel for it, it is very easy to overheat the device and board.

I would like to try one of the digital microscopes you suggested. One would think they "must" have improved to the point where are useful for SMD by now.

I don't have one myself, but they are certainly inexpensive enough to try. I am kinda used to the stereo image and variable optical zoom of my scope but if I didn't have it, I would consider the digital solution. Looking at a monitor while re-working is slightly different from peering through the eyepieces, but I'm sure you can get used to it. My scope doesn't have a camera prism so the digital version would make it easier to capture an image.

|

Re: 2011 Executive pcb outputting ~halved voltages to fan+solenoid September 04, 2021 05:14AM | Registered: 2 years ago Posts: 10 |

|

PCB Repair Video September 04, 2021 06:30PM | Admin Registered: 7 years ago Posts: 164 |

This youtube video shows what you have to do.

A few things struck me about that video.

The first is that fiberglass scratch brush is pretty large for the small vias, leaves quite the mess of tiny broken fiberglass pieces behind, and might just rip up something nearby (maybe not), not to mention being a hazard to your fingers, etc. I just use the craft knife. It's ugly, but it works, as long as one is careful. Perhaps there is a better way.

The second is that the 36 AWG enameled magnet wire used seems far too thick and heavy to replace a foil. Something like that, if attached to a foil, could easily lift the foil with one wrong move. Vias and through hole pads are stronger, but still... Wire insulation should not be needed given that the path taken by the missing foils were unobstructed by other conductors, and liquid conformal coating was applied anyway, which of coarse will insulate the wires. As previously recommended, one strand from a multi-stranded wire is just perfect: thin enough to not cause trouble, and much easier to work, plus no stripping required.

I get pc boards completely clean and shiny before each step. This aids in inspection of solder joints and fine pitch devices. The video shows the pcb with what seems to be a fair amount of residual flux or coating after each cleaning step, not really clean. To complicate matters, the MM boards have a (what was once poor) conformal coating that should be left alone except in the repair area.

The tech used a lot of Amtech NC-559-V2-TF high temperature flux that does did not evaporate under soldering to reduce solder bridging. I will order some of that flux and see how that works. By the way, "no clean" flux should be completely cleaned anyway, especially for analog circuitry, and especially when exposed to the elements. That was one of the problems with my Mosquito Magnet Defender PCB.

I assume the tech tested the board (as he said he would) before applying the MG 419d-p-gr conformal coating! I prefer clear coating to allow for later inspection, but the green coating does hide the repair details, which might be desirable in this case.

A few things struck me about that video.

The first is that fiberglass scratch brush is pretty large for the small vias, leaves quite the mess of tiny broken fiberglass pieces behind, and might just rip up something nearby (maybe not), not to mention being a hazard to your fingers, etc. I just use the craft knife. It's ugly, but it works, as long as one is careful. Perhaps there is a better way.

The second is that the 36 AWG enameled magnet wire used seems far too thick and heavy to replace a foil. Something like that, if attached to a foil, could easily lift the foil with one wrong move. Vias and through hole pads are stronger, but still... Wire insulation should not be needed given that the path taken by the missing foils were unobstructed by other conductors, and liquid conformal coating was applied anyway, which of coarse will insulate the wires. As previously recommended, one strand from a multi-stranded wire is just perfect: thin enough to not cause trouble, and much easier to work, plus no stripping required.

I get pc boards completely clean and shiny before each step. This aids in inspection of solder joints and fine pitch devices. The video shows the pcb with what seems to be a fair amount of residual flux or coating after each cleaning step, not really clean. To complicate matters, the MM boards have a (what was once poor) conformal coating that should be left alone except in the repair area.

The tech used a lot of Amtech NC-559-V2-TF high temperature flux that does did not evaporate under soldering to reduce solder bridging. I will order some of that flux and see how that works. By the way, "no clean" flux should be completely cleaned anyway, especially for analog circuitry, and especially when exposed to the elements. That was one of the problems with my Mosquito Magnet Defender PCB.

I assume the tech tested the board (as he said he would) before applying the MG 419d-p-gr conformal coating! I prefer clear coating to allow for later inspection, but the green coating does hide the repair details, which might be desirable in this case.

Sorry, only registered users may post in this forum.