Liberty MM Conversion Project

Posted by Independence

|

Re: Liberty Schematic Rev 0.1 September 04, 2020 11:17PM | Admin Registered: 7 years ago Posts: 164 |

|

Liberty MM Schematic and Board Candidate September 10, 2020 08:03PM | Registered: 3 years ago Posts: 152 |

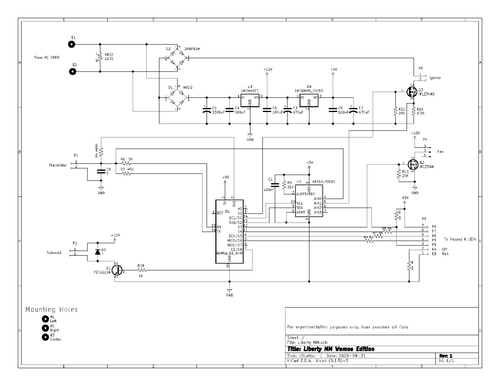

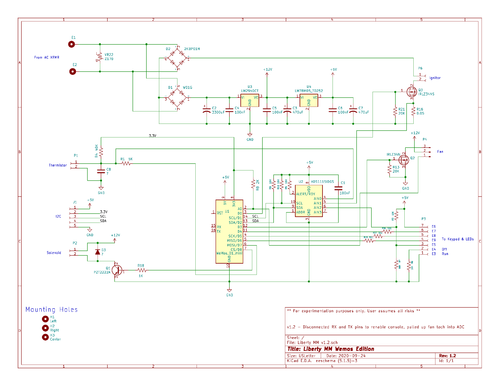

So I've been working on an initial schematic for the replacement Liberty controller. I think I've got it to the point where I'm ready to lay out the board, so I'm putting it out here for critique and feedback. It's quite a bit simpler than the original board as I removed all the feedback checks, depending just on the thermistor temperature for information on what is going on. This is the same method that is used on all their later models, so I'm quite comfortable doing that. I'm also going with a PWM driven OEM hot-surface igniter for now, and will add an external spark igniter board at a later date, should it become necessary. The version 1 schematic is shown below:

It uses the Wemos D1 mini module as the controller, which in turns uses an esp8266 module as it's main component. This module will be mounted on the underside of the main board, so that it will face upwards in normal operation. That puts the wifi antenna facing upwards and unencumbered. Although the Wemos D1 module has a single ADC input, there is an internal 320K resistive divider that scales it up to 3.2v. These internal resistors kind of skews the thermistor readings so I decided to add an external ADC, which is the commonly used ADS1115 4 channel chip. Since I will have the 0.05 ohm current resistor for the igniter anyway, I decided to keep that in there and will use an extra ADC line to monitor it. Another ADC line is used to detect the two push buttons using different pull-down resistors. That leaves me with one digital GPIO and two ADC inputs spare for future use.

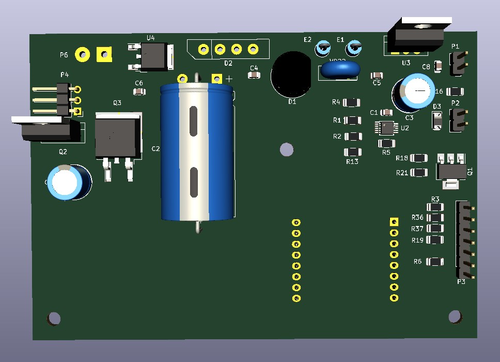

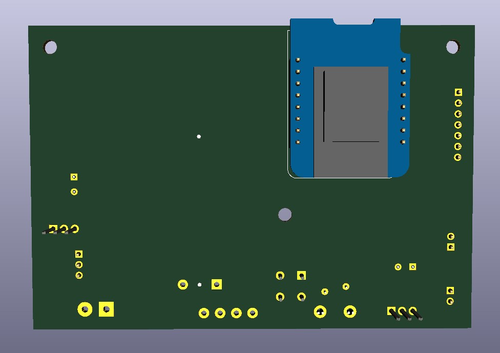

I kept most of the circuitry the same as I will be cannibalizing the OEM board for most of the components. I will also be laying out the major components in pretty much the same location as the original, except where it doesn't make sense. Here are the Kicad renderings of what the board will look like. I took shortcuts on some of the footprints so they may not have the correct shapes in the renderings, but the footprint and placement are accurate:

Based on the Defender schematic, this same circuit design should work for it, though I have no idea of the size of the board, type of connectors, etc. If someone could provide some of this information, I could potentially add different connectors types, mounting holes, etc that could make it usable on a Defender or Patriot as well.

It uses the Wemos D1 mini module as the controller, which in turns uses an esp8266 module as it's main component. This module will be mounted on the underside of the main board, so that it will face upwards in normal operation. That puts the wifi antenna facing upwards and unencumbered. Although the Wemos D1 module has a single ADC input, there is an internal 320K resistive divider that scales it up to 3.2v. These internal resistors kind of skews the thermistor readings so I decided to add an external ADC, which is the commonly used ADS1115 4 channel chip. Since I will have the 0.05 ohm current resistor for the igniter anyway, I decided to keep that in there and will use an extra ADC line to monitor it. Another ADC line is used to detect the two push buttons using different pull-down resistors. That leaves me with one digital GPIO and two ADC inputs spare for future use.

I kept most of the circuitry the same as I will be cannibalizing the OEM board for most of the components. I will also be laying out the major components in pretty much the same location as the original, except where it doesn't make sense. Here are the Kicad renderings of what the board will look like. I took shortcuts on some of the footprints so they may not have the correct shapes in the renderings, but the footprint and placement are accurate:

Based on the Defender schematic, this same circuit design should work for it, though I have no idea of the size of the board, type of connectors, etc. If someone could provide some of this information, I could potentially add different connectors types, mounting holes, etc that could make it usable on a Defender or Patriot as well.

|

Re: Liberty MM Schematic and Board Candidate September 11, 2020 06:07PM | Admin Registered: 7 years ago Posts: 164 |

This looks pretty good.

o Using the switch assembly ground as a signal directly coupled to the AD mux input: Could that be susceptible to static discharge zapping that input, or interference? Perhaps you could achieve a similar effect with 3 resistors in series: Vcc - R1 - Run - R2 - Stop - R3 - gnd, and yet another perhaps 10k resistor from Run or Stop into the mux for ESD protection?

o The 0.05 Ohm current sense resistor will reflect the PWM ramp-up waveform. Can this be synchronized with the ADC reading? If not, you may want some sort of RC low pass filter to remove or reduce the PWM pulses from this signal.

o I vote for including additional headers (e.g., +3.3, gnd, scl, scd) to connect other i2c accessories, such as the htu-21d temperature/humidity sensor (although the htu-21d reverses scl and scd), including an expanded IO port array. Perhaps this could control the Independence, if populated.

o The ads1115 might be happier on 3.3v instead of 5v

o The ADC is reading the thermistor voltage from the module 3.3v output. I suggest the IOT Defender approach that calculates the thermistor resistance from the ratio of the voltages from a fixed resistance (e.g., 20k0) into a lightly loaded (e.g., the 330k A0) input with the bottom side of the thermistor grounded to measure the thermistor contribution and open drain to measure the 3.3v. This way, power supply variations are eliminated. The bypass cap would be very small or eliminated.

o After 2 years of this approach, I do not miss the additional precision of switching scales. The 20k0 scale is accurate enough to troubleshoot those nasty "abnormal combustion" issues I wrote about earlier. This would save two outputs and some logic to do the switching. Plus the nuisance of the calibrating the overlapping ranges. And no issues with different drive currents.

o Hey, it is really handy to have access to the console Tx and Rx for those rainy nights when the system keeps crashing. Another NodeMCU connected to those ports can transmit the serial output to a dry location for analysis. A header with ground, Tx, Rx, and maybe power might come in very handy.

o I thought D0 couldn't do PWM ??? It is perfect for driving an LED, though.

o The 511 ohm LED resistors may be too large for the 3.3 volt output, resulting in dim LEDs. What a waste of precious IO. Another reason to perhaps put in an expander.

o I suppose you will should support the existing Liberty error codes, which you can do perhaps with clever analysis of the temperature vs time. The fan error might be a challenge, since you are not using the fan output...

I really like the smaller form factor D1 mini, except for the cheaper USB chip, and no flash button, although I don't use the flash button anyway, only RTS for reset and OTA. I assume you are using a 4 mb flash unit, some are 1 mb. Either way, there is enough flash memory, but still... I suggest including telnet and ftp, or some other solution for OTA programming. Still it is fun to telnet into the unit. I modified ftp to allow a command (rhelp) to reboot the system.

My Defender and Patriot are catching mosquitos now, so I can't get dimensions. I agree it would a good idea to consider and perhaps accommodate those dimensions, but I can't do it right now.

o Using the switch assembly ground as a signal directly coupled to the AD mux input: Could that be susceptible to static discharge zapping that input, or interference? Perhaps you could achieve a similar effect with 3 resistors in series: Vcc - R1 - Run - R2 - Stop - R3 - gnd, and yet another perhaps 10k resistor from Run or Stop into the mux for ESD protection?

o The 0.05 Ohm current sense resistor will reflect the PWM ramp-up waveform. Can this be synchronized with the ADC reading? If not, you may want some sort of RC low pass filter to remove or reduce the PWM pulses from this signal.

o I vote for including additional headers (e.g., +3.3, gnd, scl, scd) to connect other i2c accessories, such as the htu-21d temperature/humidity sensor (although the htu-21d reverses scl and scd), including an expanded IO port array. Perhaps this could control the Independence, if populated.

o The ads1115 might be happier on 3.3v instead of 5v

o The ADC is reading the thermistor voltage from the module 3.3v output. I suggest the IOT Defender approach that calculates the thermistor resistance from the ratio of the voltages from a fixed resistance (e.g., 20k0) into a lightly loaded (e.g., the 330k A0) input with the bottom side of the thermistor grounded to measure the thermistor contribution and open drain to measure the 3.3v. This way, power supply variations are eliminated. The bypass cap would be very small or eliminated.

o After 2 years of this approach, I do not miss the additional precision of switching scales. The 20k0 scale is accurate enough to troubleshoot those nasty "abnormal combustion" issues I wrote about earlier. This would save two outputs and some logic to do the switching. Plus the nuisance of the calibrating the overlapping ranges. And no issues with different drive currents.

o Hey, it is really handy to have access to the console Tx and Rx for those rainy nights when the system keeps crashing. Another NodeMCU connected to those ports can transmit the serial output to a dry location for analysis. A header with ground, Tx, Rx, and maybe power might come in very handy.

o I thought D0 couldn't do PWM ??? It is perfect for driving an LED, though.

o The 511 ohm LED resistors may be too large for the 3.3 volt output, resulting in dim LEDs. What a waste of precious IO. Another reason to perhaps put in an expander.

o I suppose you will should support the existing Liberty error codes, which you can do perhaps with clever analysis of the temperature vs time. The fan error might be a challenge, since you are not using the fan output...

I really like the smaller form factor D1 mini, except for the cheaper USB chip, and no flash button, although I don't use the flash button anyway, only RTS for reset and OTA. I assume you are using a 4 mb flash unit, some are 1 mb. Either way, there is enough flash memory, but still... I suggest including telnet and ftp, or some other solution for OTA programming. Still it is fun to telnet into the unit. I modified ftp to allow a command (rhelp) to reboot the system.

My Defender and Patriot are catching mosquitos now, so I can't get dimensions. I agree it would a good idea to consider and perhaps accommodate those dimensions, but I can't do it right now.

|

Re: Liberty MM Schematic and Board Candidate September 12, 2020 05:03AM | Registered: 3 years ago Posts: 152 |

Well, thanks for taking the time to look it over. A second opinion is always useful.

>Could that be susceptible to static discharge zapping that input, or interference?

It IS a membrane button, so I think that provides some degree of protection, but having a path to ground all the time wouldn't hurt so I added an extra resistor to ground.

> ..some sort of RC low pass filter to remove or reduce the PWM pulses from this signal.

The goal of that current sensor is just to check that the igniter is still working, so I won't even check it until it has reached steady state. I wasn't planning on measuring the current during the PWM ramp up. For the record, the deadbug igniter controller has been working very well the last couple of days of starts. The code I posted reflects what I am using now. It's a two stage ramp and the current during the ramp ups never exceeds the final steady state value. Ignition is detected at about 45 seconds after the igniter is turned on, and turning it off at 60 secs has been working fine.

I also decided to add some circuitry to detect that the fan is running. It's just a simple Zener diode voltage drop to 3.3v into a digital input of the Wemos. Arduino has a pulsein() function that can measure the width of the pulse, so simple enough.

> o I vote for including additional headers (e.g., +3.3, gnd, scl, scd) to connect other i2c accessories,

I added an i2c header with both 3.3v and 5v power.

> o The ads1115 might be happier on 3.3v instead of 5v

It will work all the way to 5.5v and I wanted it to be able to measure up to 5v. Fortunately the Wemos is 5V tolerant and the i2c bus works fine in this mode.

> o The ADC is reading the thermistor voltage from the module 3.3v output. I suggest the IOT Defender

> approach that calculates the thermistor resistance from the ratio of the voltages from a fixed resist

I'll have to look at your IOT Defender blog to see exactly what you are proposing. I did it the 2 stage way, ala Independence, even though the Liberty doesn't need to measure as high temperatures. Since all the code is already written to automatically handle the two stage system and I have all the existing worksheets for temperature vs voltage, for me, it was an easier way to go.

> o Hey, it is really handy to have access to the console Tx and Rx for those rainy nights when the system keeps crashing.

I know you used the LUA environment for your NodeMCU project, but if you didn't know, the Arduino environment supports a full serial console environment via the USB port. It's trivial to include simple CLI commands and responses in your code and control and view your program via the Arduino IDE console. All my debugging is done this way, and sometimes you end up with quite a list of debugging commands and functions! Also, the whole point of using the Wemos 8266 controller is to do everything by wifi anyway.

> o I thought D0 couldn't do PWM ???

The Wemos D1 esp8266 module can do PWM on all the digital GPIO pins.

> o The 511 ohm LED resistors may be too large for the 3.3 volt output, resulting in dim LEDs.

The LEDs are pulled down from 5V by the Wemos output, so no problem there.

> What a waste of precious IO. Another reason to perhaps put in an expander.

That's why I like the Atmega 32u4 chip. Plenty of GPIO and ADC pins. But you gotta love the Wifi on these modules, so that's the compromise.

> o I suppose you will should support the existing Liberty error codes,

I don't even know what the Liberty error codes are, but before I added the Wifi Web interface to my Independence, I had developed a multitude of flashing LED signals. The Independence has a single combined RED/GREEN LED. So you could get green, red, and orange colors. I actually had an LED handler that could blink each color a number of times. So, while it was warming up, for example, the orange LED would be on. I would start to flash it an increasing number of times as it approached RUN mode. It was my way of telling the temperature. 1 flash was a certain temperature range, 2 flash another, etc. And then when it turned green, it would also flash green a number of times to indicated what temperature range it was currently operating in. And obviously, if it errored out, it would sit there and blink the red LED a number of times. I had a blink code for every possible error.

I left the code in even though all the temperatures and states are now available via the Web interface and MQTT, and since I will be reusing the code, I guess it will remain. Having 3 separate LEDs to play with expands the possibilities though!

> I suggest including telnet and ftp, or some other solution for OTA programming.

The Arduino platform has a lot of available libraries, including OTA programming. I've played with OTA programming but it's not a priority for me. My MMs are nearby and it's easy enough to go out there with a Macbook and plug into the USB and program it, which doesn't happen very often. I try to use the Web interface for everything and having it makes it easy to integrate into Smarthome. There's no point in doing it since it's already automated, but it would be trivial to add the Independence to my Smarthome and be able to say 'Alexa, turn on/off Mosquito Magnet'

> My Defender and Patriot are catching mosquitos now, so I can't get dimensions.

That's ok, this is going to be version 1 of the PCB, and we all know it never ends at 1.0...

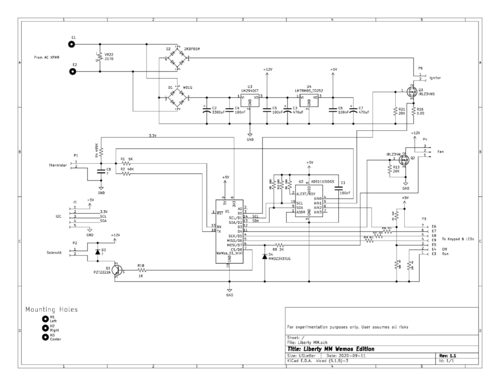

So, having said that, here is version 1.1 of the schematic, based on your comments:

>Could that be susceptible to static discharge zapping that input, or interference?

It IS a membrane button, so I think that provides some degree of protection, but having a path to ground all the time wouldn't hurt so I added an extra resistor to ground.

> ..some sort of RC low pass filter to remove or reduce the PWM pulses from this signal.

The goal of that current sensor is just to check that the igniter is still working, so I won't even check it until it has reached steady state. I wasn't planning on measuring the current during the PWM ramp up. For the record, the deadbug igniter controller has been working very well the last couple of days of starts. The code I posted reflects what I am using now. It's a two stage ramp and the current during the ramp ups never exceeds the final steady state value. Ignition is detected at about 45 seconds after the igniter is turned on, and turning it off at 60 secs has been working fine.

I also decided to add some circuitry to detect that the fan is running. It's just a simple Zener diode voltage drop to 3.3v into a digital input of the Wemos. Arduino has a pulsein() function that can measure the width of the pulse, so simple enough.

> o I vote for including additional headers (e.g., +3.3, gnd, scl, scd) to connect other i2c accessories,

I added an i2c header with both 3.3v and 5v power.

> o The ads1115 might be happier on 3.3v instead of 5v

It will work all the way to 5.5v and I wanted it to be able to measure up to 5v. Fortunately the Wemos is 5V tolerant and the i2c bus works fine in this mode.

> o The ADC is reading the thermistor voltage from the module 3.3v output. I suggest the IOT Defender

> approach that calculates the thermistor resistance from the ratio of the voltages from a fixed resist

I'll have to look at your IOT Defender blog to see exactly what you are proposing. I did it the 2 stage way, ala Independence, even though the Liberty doesn't need to measure as high temperatures. Since all the code is already written to automatically handle the two stage system and I have all the existing worksheets for temperature vs voltage, for me, it was an easier way to go.

> o Hey, it is really handy to have access to the console Tx and Rx for those rainy nights when the system keeps crashing.

I know you used the LUA environment for your NodeMCU project, but if you didn't know, the Arduino environment supports a full serial console environment via the USB port. It's trivial to include simple CLI commands and responses in your code and control and view your program via the Arduino IDE console. All my debugging is done this way, and sometimes you end up with quite a list of debugging commands and functions! Also, the whole point of using the Wemos 8266 controller is to do everything by wifi anyway.

> o I thought D0 couldn't do PWM ???

The Wemos D1 esp8266 module can do PWM on all the digital GPIO pins.

> o The 511 ohm LED resistors may be too large for the 3.3 volt output, resulting in dim LEDs.

The LEDs are pulled down from 5V by the Wemos output, so no problem there.

> What a waste of precious IO. Another reason to perhaps put in an expander.

That's why I like the Atmega 32u4 chip. Plenty of GPIO and ADC pins. But you gotta love the Wifi on these modules, so that's the compromise.

> o I suppose you will should support the existing Liberty error codes,

I don't even know what the Liberty error codes are, but before I added the Wifi Web interface to my Independence, I had developed a multitude of flashing LED signals. The Independence has a single combined RED/GREEN LED. So you could get green, red, and orange colors. I actually had an LED handler that could blink each color a number of times. So, while it was warming up, for example, the orange LED would be on. I would start to flash it an increasing number of times as it approached RUN mode. It was my way of telling the temperature. 1 flash was a certain temperature range, 2 flash another, etc. And then when it turned green, it would also flash green a number of times to indicated what temperature range it was currently operating in. And obviously, if it errored out, it would sit there and blink the red LED a number of times. I had a blink code for every possible error.

I left the code in even though all the temperatures and states are now available via the Web interface and MQTT, and since I will be reusing the code, I guess it will remain. Having 3 separate LEDs to play with expands the possibilities though!

> I suggest including telnet and ftp, or some other solution for OTA programming.

The Arduino platform has a lot of available libraries, including OTA programming. I've played with OTA programming but it's not a priority for me. My MMs are nearby and it's easy enough to go out there with a Macbook and plug into the USB and program it, which doesn't happen very often. I try to use the Web interface for everything and having it makes it easy to integrate into Smarthome. There's no point in doing it since it's already automated, but it would be trivial to add the Independence to my Smarthome and be able to say 'Alexa, turn on/off Mosquito Magnet'

> My Defender and Patriot are catching mosquitos now, so I can't get dimensions.

That's ok, this is going to be version 1 of the PCB, and we all know it never ends at 1.0...

So, having said that, here is version 1.1 of the schematic, based on your comments:

|

Here it is, first version of the Liberty controller... September 19, 2020 09:05PM | Registered: 3 years ago Posts: 152 |

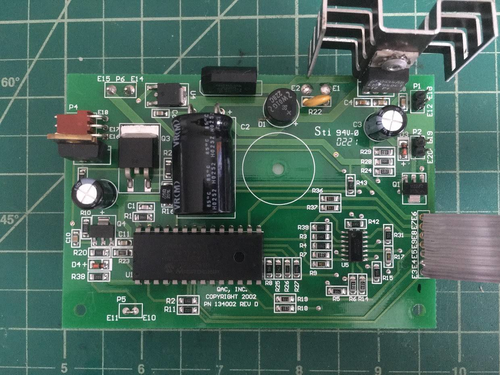

Well, mosquito season is pretty much over where I live, so this project well may continue next spring, but I just received the fabricated PCB, so here is the first version of the Liberty controller. For comparison, here is how the original Liberty MM controller board looks like:

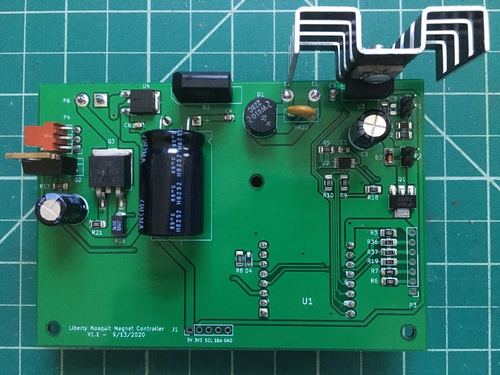

And here is how the new controller ended up, based on the V1.1 schematic in the previous post:

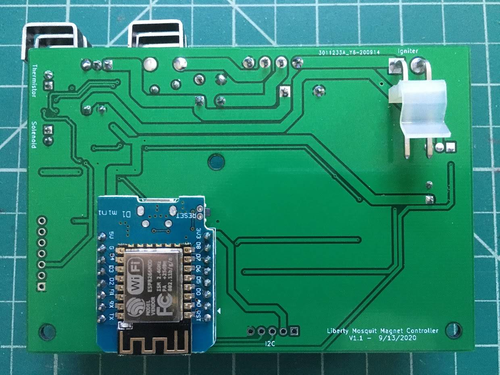

and the back side:

(continued on next post)

And here is how the new controller ended up, based on the V1.1 schematic in the previous post:

and the back side:

(continued on next post)

|

Re: Here it is, first version of the Liberty controller... September 19, 2020 09:13PM | Registered: 3 years ago Posts: 152 |

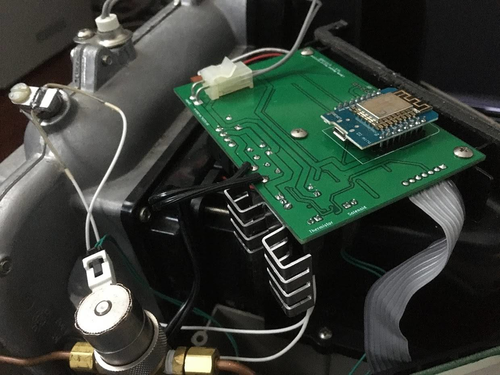

And here is how it looks installed in the Liberty:

As mentioned earlier, I pretty much kept most of the mechanical and electrical design, where possible. After I received the board, it occurred to me that the top of the Liberty case slopes down a bit so there might be a clearance issue with the Wemos board, but even with it raised up, it clears fine.

A quick check of the board seems to indicate I didn't screw anything up and everything should work as expected. I will start porting over my Independence code to this controller but probably won't get to test it in a real environment until next spring/summer.

Happy Fall/Winter... :)

As mentioned earlier, I pretty much kept most of the mechanical and electrical design, where possible. After I received the board, it occurred to me that the top of the Liberty case slopes down a bit so there might be a clearance issue with the Wemos board, but even with it raised up, it clears fine.

A quick check of the board seems to indicate I didn't screw anything up and everything should work as expected. I will start porting over my Independence code to this controller but probably won't get to test it in a real environment until next spring/summer.

Happy Fall/Winter... :)

|

Re: Here it is, first version of the Liberty controller... September 22, 2020 02:36PM | Registered: 3 years ago Posts: 152 |

Uh oh, spoke to soon. I thought I could multiplex the RX and TX pins as i/o but I was wrong and you can't use them as i/o if you want the console to work, so those pins have been freed up since I need the console to debug. The 2 stage ADC voltage divider has been simplified to use a single digital pin. I also thought the fan input was a signal with a frequency that reflected the RPM, but it's actually just an inverted version of the driving PWM signal. So that signal has been modified to be filtered into an input voltage for the built in ADC. These mods could be done via simple rework, so I didn't re-spin the board. So here is V1.2 of the schematic:

9/24/20 - Edited the schematic to just feed the pulled-up tach input into the ADC. Not sure what to do with it at this point...

Edited 2 time(s). Last edit at 09/24/2020 03:41PM by Independence.

9/24/20 - Edited the schematic to just feed the pulled-up tach input into the ADC. Not sure what to do with it at this point...

Edited 2 time(s). Last edit at 09/24/2020 03:41PM by Independence.

|

No Tach Signal? September 23, 2020 05:06AM | Admin Registered: 7 years ago Posts: 164 |

I have to say your board looks great!

...I also thought the fan input was a signal with a frequency that reflected the RPM, but it's actually just an inverted version of the driving PWM signal...

That's disappointing. I thought so, too. What is the point of such a signal? And how does a fan do inversion?

Perhaps a small tach signal is riding on the large PWM waveform, so is not being detected. I would expect the tach signal to be referenced to the 'ground' lead, which here is being driven. If the fan is 100% on, just grounded, can you see a signal? If so, driving the fan 'hot' side may be the simplest approach, but it requires new and different components, and messes up the layout. Depending on the tach signal level and PWM frequency, a differential measurement using two ADS1115 pins and some resistors might work. Fortunately, fan speed measurement is not critical for operation.

Anyway, I hope you can get this going before the mosquitos disappear.

...I also thought the fan input was a signal with a frequency that reflected the RPM, but it's actually just an inverted version of the driving PWM signal...

That's disappointing. I thought so, too. What is the point of such a signal? And how does a fan do inversion?

Perhaps a small tach signal is riding on the large PWM waveform, so is not being detected. I would expect the tach signal to be referenced to the 'ground' lead, which here is being driven. If the fan is 100% on, just grounded, can you see a signal? If so, driving the fan 'hot' side may be the simplest approach, but it requires new and different components, and messes up the layout. Depending on the tach signal level and PWM frequency, a differential measurement using two ADS1115 pins and some resistors might work. Fortunately, fan speed measurement is not critical for operation.

Anyway, I hope you can get this going before the mosquitos disappear.

|

Re: No Tach Signal? September 23, 2020 03:32PM | Registered: 3 years ago Posts: 152 |

Ahh.. as you surmised, driving the ground with PWM is resulting in what I'm seeing. The fan tach output is an open collector to ground, and when pulled up, with the fan fully driven, I do see a correct frequency. I don't think it's worth redesigning, so I think I am going to integrate the signal and only check it when the fan is set for full speed. Maybe, once a day, set the fan to full speed and check the voltage for half the pull up voltage. Then restore normal speed.

Speaking of fan speed, it appears the Liberty doesn't run at full speed, but at some level below it. I remember this because I saw the PWM signal when I tried to measure the tach. Unfortunately, I didn't measure all the duty cycles and now I don't have the OEM controller running anymore, so I don't know what to set the run speed of the fan. In looking at the Arduino Defender code, it's like between 205, 210 out of 255. I guess I'll start with those numbers first....

Speaking of fan speed, it appears the Liberty doesn't run at full speed, but at some level below it. I remember this because I saw the PWM signal when I tried to measure the tach. Unfortunately, I didn't measure all the duty cycles and now I don't have the OEM controller running anymore, so I don't know what to set the run speed of the fan. In looking at the Arduino Defender code, it's like between 205, 210 out of 255. I guess I'll start with those numbers first....

|

Re: Here it is, first version of the Liberty controller... September 25, 2020 10:27PM | Registered: 3 years ago Posts: 152 |

So, the weather has warmed up a bit here and I've had a chance to port my Independence code to the new esp8266 based Liberty controller. All the code ported over without any problems, which is a testament to the Arduino architecture. I now have the same operational functionality of my Independence MM on a Liberty MM, minus the battery operation mode. The only issue I had was with the thermistor readings, which I'll cover later in this post.

I've already posted pictures of the controller board mounted in the Liberty, so this post will cover mostly the functionality. To recap, the idea was to re-configure the Liberty so it had wireless network control, as well as full control of it's operation. The Independence was done with an Atmega 32U4 controller chip, with a Wemos D1 mini module added later to provide the WiFi access. For the Liberty, it was decided to use the Wemos D1 mini for all the functions. The basic software includes the following:

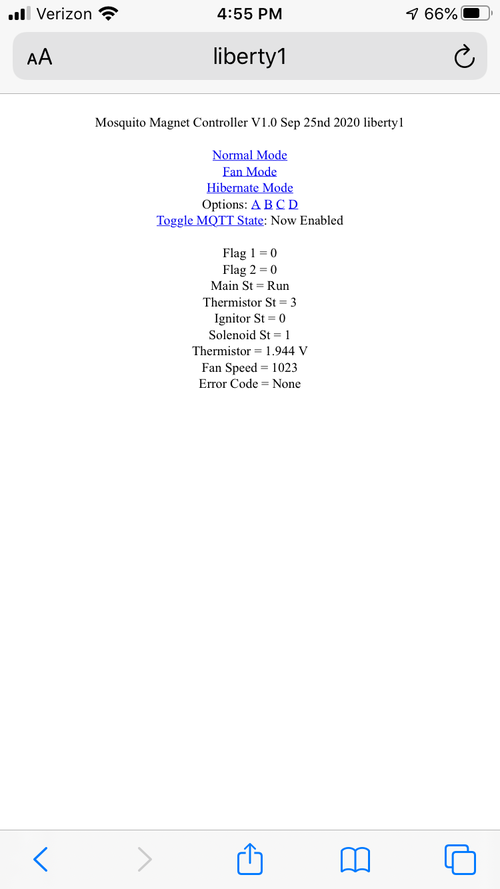

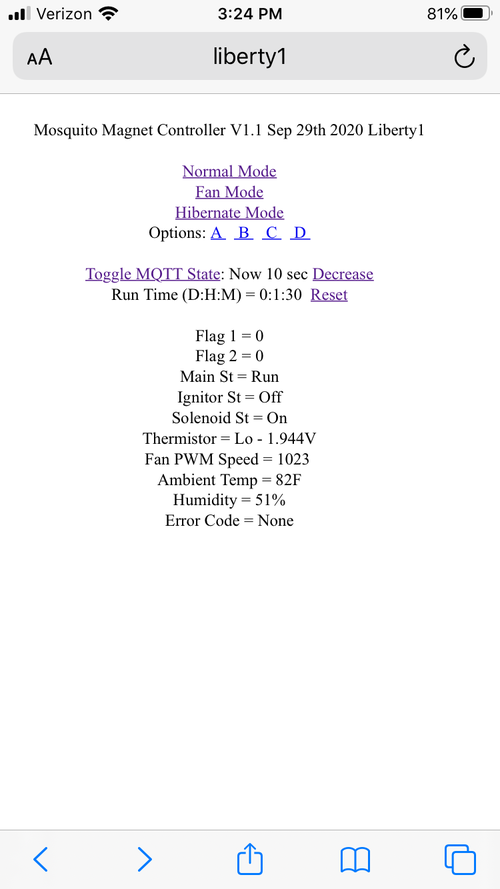

This is what the web interface looks like. It's pretty much the same as my Independence.

The top part of the interface is used to control the Liberty. It's pretty much self explanatory. Option A-D are placeholders to easily add test functions without changing the interface. Right now, they set different fan speeds as I am experiment to see if there is a difference. The lower portion of the web screen just provides a status of the Liberty. They are also reported via MQTT, if enabled. The web API is super simple, you just send the http command for action. For example, to set the unit into fan mode, you just send it the request http://liberty1/fan. Yes, there is no security and anyone that has access to your network can control your MM. You COULD use https and obfuscate your URL with a key only you know, but I don't really care...

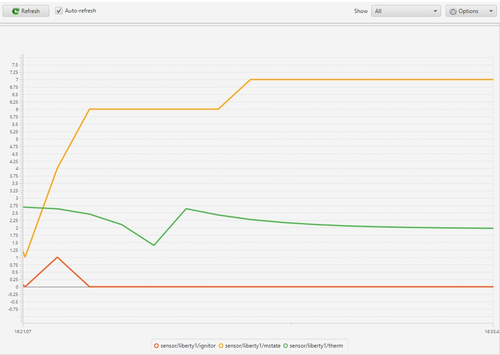

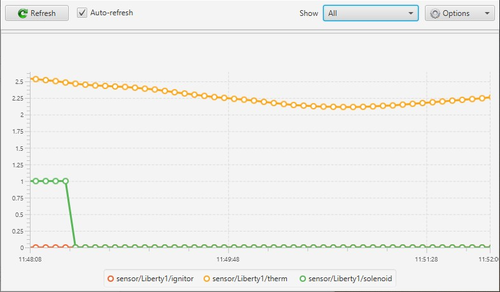

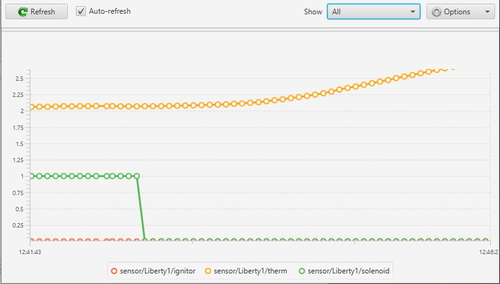

Here's a startup plot from the MQTT data:

Not much to see compared to the Independence. I'm only sending it once every minute, so the startup is somewhat compressed. The orange line is the state, and you can see it go from purge (1), to ignite (4), to warmup (6), to run mode (7). Since the igniter stays on for barely a minute, often it doesn't even register. The green line is the thermistor, with it's two stage setting. It turns out it doesn't get that hot compared to the Independence.

Well, that's about it. It ran last night and it's running now, but I don't really have any more mosquitoes to catch, so the real test will come next year. I was going to cover some of the other things I found in this post, but I think that's enough for this post. I will make another post for those items.

I've already posted pictures of the controller board mounted in the Liberty, so this post will cover mostly the functionality. To recap, the idea was to re-configure the Liberty so it had wireless network control, as well as full control of it's operation. The Independence was done with an Atmega 32U4 controller chip, with a Wemos D1 mini module added later to provide the WiFi access. For the Liberty, it was decided to use the Wemos D1 mini for all the functions. The basic software includes the following:

- The Liberty now powers on in the ON state always. So, if you loose power, when it returns, the Liberty will go through its power on cycle. You can still turn it on and off using the buttons, or via Wifi, if you so desire.

- To deal with short outages, the Liberty will not go through it's ignite cycle until the thermistor is above a certain value. It will go through the purge stage, but will not advance to the ignition or gas stage until the thermistor temperature has reached a certain level.

- The igniter has a PWM ramped turn-on sequence stretched out over 20 seconds. The goal was to preserve the igniter by preventing the 'shock' of a hard current turn-on. Others have had success with this method, so lets see how it works out.

- The current turn-on sequence is to purge for 25 seconds, and then, if the thermistor is within range, start the igniter ramp, along with turning on the gas. The igniter stays on for a total of 65 seconds, or until ignition is detected via a 0.1v change in thermistor voltage. If no ignition is detected within 4 mins, it shuts off the gas and errors out.

- Once ignition is detected, it proceeds to the warm-up stage, where it will wait up to 30 mins to reach operating temperature. If it fails to do so in this time, it will error out.

- Once it reaches operating temperature, it will monitor for over and under temperatures and error out appropriately.

- During the entire start-up and run process, the LEDs provide visual indications of the state, in case WiFi access is not available. When the unit powers on, the Yellow LED comes on solid. It stays this way until ignition is detected, whereupon it changes to a single yellow blink. There are then up to 4 yellow blink sequences that indicates the range of temperate that the unit is currently in. When it reaches operating temperature, the Green LED comes on solid. The Green LED is then blinked to indicate the operating temperature range. I currently only have 1 blink range as I don't have a good feel for the operating temperatures of the Liberty yet.

- If the unit errors out for any reason, it will sit there and blink the Red LED a number of times that indicates which error caused it to error out.

- If the unit is put into Fan only mode via Wifi, it will alternate between the Green and Yellow LED.

- The Liberty controller will join your Wifi WAP as a client and will then appear on your network as an accessible device. It has a simple Web interface that can be used via any browser, or can be used to receive http commands from other web controllers. It also has a MQTT interface with which to report it's operating parameters. It can be enabled or disabled as needed.

This is what the web interface looks like. It's pretty much the same as my Independence.

The top part of the interface is used to control the Liberty. It's pretty much self explanatory. Option A-D are placeholders to easily add test functions without changing the interface. Right now, they set different fan speeds as I am experiment to see if there is a difference. The lower portion of the web screen just provides a status of the Liberty. They are also reported via MQTT, if enabled. The web API is super simple, you just send the http command for action. For example, to set the unit into fan mode, you just send it the request http://liberty1/fan. Yes, there is no security and anyone that has access to your network can control your MM. You COULD use https and obfuscate your URL with a key only you know, but I don't really care...

Here's a startup plot from the MQTT data:

Not much to see compared to the Independence. I'm only sending it once every minute, so the startup is somewhat compressed. The orange line is the state, and you can see it go from purge (1), to ignite (4), to warmup (6), to run mode (7). Since the igniter stays on for barely a minute, often it doesn't even register. The green line is the thermistor, with it's two stage setting. It turns out it doesn't get that hot compared to the Independence.

Well, that's about it. It ran last night and it's running now, but I don't really have any more mosquitoes to catch, so the real test will come next year. I was going to cover some of the other things I found in this post, but I think that's enough for this post. I will make another post for those items.

|

Some Thermistor musings... September 26, 2020 02:21AM | Registered: 3 years ago Posts: 152 |

As part of the testing I did on the software for the Liberty, I seem to be seeing a difference in the thermistor readings. I have limited data on the Liberty and in fact, the only data I have of it are the couple of DVM thermocouple based readings I made earlier. The thermocouple was taped with thermal grease right next to the thermistor. Those readings seemed reasonable and the Liberty reached operating mode at an indicated thermocouple temperature of about 110C. Well, after bringing up the new Liberty controller, I am seeing some different results from what I expected.

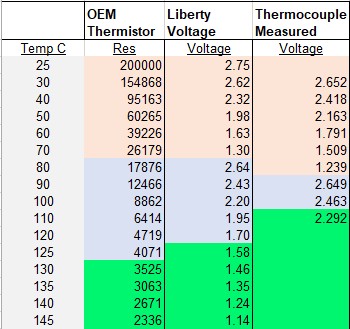

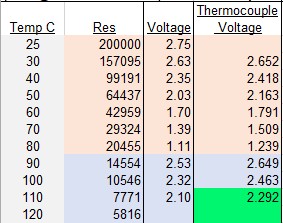

Take a look at these readings:

The first two columns are the expected values from the OEM thermistor. The 3rd column is the expected measured voltage from the ADC based on the high (25-70C) and low (80C upwards) ADC settings, based on the thermistor resistance. The 4th column, however is what was measured by the ADC, based on the thermocouple temperature. It is significantly different and I'm suspecting that I don't have same 200K@25 B25/85=4623 thermistor as I do on the Independence.

The numbers are closer with the Digikey KC014G-ND thermistor:

What is unusual is that even with the Digikey thermistor, it is still reading low, i.e. thermistor voltage is telling me the calculated temperature is lower than what the thermocouple is telling me. And I would expect the thermocouple to read a bit lower than the thermistor, due to worse thermal contact. For now, I am just adjusting my temperature thresholds based on the measured data, but at some point, I may have to test the thermistor to see if I can account for the difference.

The other thing I noticed about the Liberty is that the thermal behavior of the cat chamber is different from the Independence. On the Liberty, when I shut off the gas after ignition, the temperature continues to rise for at least a minute or two before it starts to decline. On the Independence, it starts to drop almost immediately. I think the combustion and reaction inside the cat chambers are slightly different, with the Liberty taking longer to respond thermally.

The nights are getting too cool to bother to run the MMs and the days are not hot enough to get a summer type run, so I'm probably going to bag it till next year.

Take a look at these readings:

The first two columns are the expected values from the OEM thermistor. The 3rd column is the expected measured voltage from the ADC based on the high (25-70C) and low (80C upwards) ADC settings, based on the thermistor resistance. The 4th column, however is what was measured by the ADC, based on the thermocouple temperature. It is significantly different and I'm suspecting that I don't have same 200K@25 B25/85=4623 thermistor as I do on the Independence.

The numbers are closer with the Digikey KC014G-ND thermistor:

What is unusual is that even with the Digikey thermistor, it is still reading low, i.e. thermistor voltage is telling me the calculated temperature is lower than what the thermocouple is telling me. And I would expect the thermocouple to read a bit lower than the thermistor, due to worse thermal contact. For now, I am just adjusting my temperature thresholds based on the measured data, but at some point, I may have to test the thermistor to see if I can account for the difference.

The other thing I noticed about the Liberty is that the thermal behavior of the cat chamber is different from the Independence. On the Liberty, when I shut off the gas after ignition, the temperature continues to rise for at least a minute or two before it starts to decline. On the Independence, it starts to drop almost immediately. I think the combustion and reaction inside the cat chambers are slightly different, with the Liberty taking longer to respond thermally.

The nights are getting too cool to bother to run the MMs and the days are not hot enough to get a summer type run, so I'm probably going to bag it till next year.

|

Re: No Tach Signal? September 26, 2020 11:27PM | Admin Registered: 7 years ago Posts: 164 |

...The thermocouple was taped with thermal grease right next to the thermistor. ...

Was it attached to the metal bracket holding the thermistor, and away from the case? I remember that the Digikey thermistor is supposed to be within 1% or so. There is a (low) thermal impedance in that bracket, and that the end (plus your thermocouple) form a thermal shunt to the ambient air around the case. I don't know how much thermal mass and loss is coming from the thermocouple, it may be significant.

the 4th column ... is significantly different

(I was confused because the numbers in the 4th column are identical between the two charts in your post. Column 3, the 'expected' voltage, is different.)

There must be an explanation. Perhaps the 4th column voltages are off because the +3.3 driving voltage is changing as the system heats up. That's one reason the NodeMCU design measures resistor ratios rather than voltages, to calculate the thermistor resistance, eliminating that potential error source.

An interesting idea to work with voltages instead of °C. That calculation requires a table, and a log function, which was not in the lua math library... Had to roll my own. It wasn't that difficult. The table is based on the DK thermistor specs, so is I suppose not so accurate. But it is not too far off, either, compared to an IR temperature probe. The benefit was that a 5°C temperature rise for combustion detection works at any temperature.

...when I shut off the gas after ignition, the temperature continues to rise for at least a minute...

That's the tank gas valve, in the warm up phase, no? The gas does not really stop for a while after shutting the tank valve. The electric valve is much quicker. That said, I had an issue 2 years ago that when the unit was running steady, something would trigger a 10-15° temperature rise then a combustion failure. That rise would also frequently occur when shutting off the electric gas valve remotely. I called that "abnormal combustion." This was fixed by replacing the regulator. See the blog.

All in all, it looks like your system is excellent. It should be reliable if you add sufficient conformal coating. It needs a weatherproof laminated guide to the blinking lights! And a warning label that it will start when plugged in. I avoided all that by making the unit (switch and LED UI) behave exactly the same as the Defender. Still, it might be good to save the on/off state so that it persists during a power failure, just like the other adjustable settings.

Was it attached to the metal bracket holding the thermistor, and away from the case? I remember that the Digikey thermistor is supposed to be within 1% or so. There is a (low) thermal impedance in that bracket, and that the end (plus your thermocouple) form a thermal shunt to the ambient air around the case. I don't know how much thermal mass and loss is coming from the thermocouple, it may be significant.

the 4th column ... is significantly different

(I was confused because the numbers in the 4th column are identical between the two charts in your post. Column 3, the 'expected' voltage, is different.)

There must be an explanation. Perhaps the 4th column voltages are off because the +3.3 driving voltage is changing as the system heats up. That's one reason the NodeMCU design measures resistor ratios rather than voltages, to calculate the thermistor resistance, eliminating that potential error source.

An interesting idea to work with voltages instead of °C. That calculation requires a table, and a log function, which was not in the lua math library... Had to roll my own. It wasn't that difficult. The table is based on the DK thermistor specs, so is I suppose not so accurate. But it is not too far off, either, compared to an IR temperature probe. The benefit was that a 5°C temperature rise for combustion detection works at any temperature.

...when I shut off the gas after ignition, the temperature continues to rise for at least a minute...

That's the tank gas valve, in the warm up phase, no? The gas does not really stop for a while after shutting the tank valve. The electric valve is much quicker. That said, I had an issue 2 years ago that when the unit was running steady, something would trigger a 10-15° temperature rise then a combustion failure. That rise would also frequently occur when shutting off the electric gas valve remotely. I called that "abnormal combustion." This was fixed by replacing the regulator. See the blog.

All in all, it looks like your system is excellent. It should be reliable if you add sufficient conformal coating. It needs a weatherproof laminated guide to the blinking lights! And a warning label that it will start when plugged in. I avoided all that by making the unit (switch and LED UI) behave exactly the same as the Defender. Still, it might be good to save the on/off state so that it persists during a power failure, just like the other adjustable settings.

|

Re: No Tach Signal? September 27, 2020 09:15PM | Registered: 3 years ago Posts: 152 |

> Was it attached to the metal bracket holding the thermistor, and away from the case?

Yes, it was taped right next to where the thermistor is notched into the bracket, with thermal grease. The thermocouple is a tiny device, less than a 1.5mm size bead, and shouldn't affect the overall temperature. See pic:

> (I was confused because the numbers in the 4th column are identical between the two charts in your post.

I did a poor job explaining it. Column 3 in both tables is the expected/calculated thermistor voltage by temperature, based on the type of thermistor and resistors used. Column 4 is the actual thermistor voltage measured by the controller, but mapped to the temperature indicated by the thermocouple. I don't think the differences can be accounted for by any minute changes in the 3.3v driving voltage. The only definitive way to find out is to measure the thermistor over a range of temperature, and I may do that in the down season.

> An interesting idea to work with voltages instead of °C.

It never really occurred to me to convert to temperature as I had always worked with the thermistor calculated voltages. All my data for the Independence was derived by using a potentiometer on it and finding the transitions points and corresponding thermistor voltages. The state machine works off voltage thresholds. If I find the real characteristics of the thermistor, I will just build a new temperature table and change the voltage thresholds points in the program to reflect it.

> The benefit was that a 5°C temperature rise for combustion detection works at any temperature.

I'll give you that one, but the voltage changes at the normal ignition temperatures range are pretty large so it's never been a problem.

> That's the tank gas valve, in the warm up phase, no? The gas does not really stop for a while after

> shutting the tank valve. The electric valve is much quicker.

I was actually shutting it off using the electric valve in both cases, and so expected to see a faster response. Not only does it not decrease in temperature, it actually continues to rise for almost 2 mins before it starts to decrease. I will play with and monitor this more next year.

> It needs a weatherproof laminated guide to the blinking lights! And a warning label that it will start when

> plugged in.

Um, I'm not making a product here.. :) I'm the only person using these devices. And the LEDs are only the visual backup. The same data is available on the web interface in a more verbose manner.

> Still, it might be good to save the on/off state so that it persists during a power failure,

Yes, I will be using the EEPROM on the unit to store the last state so that it would power back up in that state. That's the more logical way to do it... I'm also going to add an ambient temperature sensor as I like having that to correlate to the chamber temperature.

It's been running very nicely for the last 2 days. Since I don't really have any mosquitoes left, I basically have it run two short propane cycles at dusk and dawn, just as a test. My igniter ramp cycles must be good enough as it's been working flawlessly so far. The real test will be next year when I run it that way for several months.

Yes, it was taped right next to where the thermistor is notched into the bracket, with thermal grease. The thermocouple is a tiny device, less than a 1.5mm size bead, and shouldn't affect the overall temperature. See pic:

> (I was confused because the numbers in the 4th column are identical between the two charts in your post.

I did a poor job explaining it. Column 3 in both tables is the expected/calculated thermistor voltage by temperature, based on the type of thermistor and resistors used. Column 4 is the actual thermistor voltage measured by the controller, but mapped to the temperature indicated by the thermocouple. I don't think the differences can be accounted for by any minute changes in the 3.3v driving voltage. The only definitive way to find out is to measure the thermistor over a range of temperature, and I may do that in the down season.

> An interesting idea to work with voltages instead of °C.

It never really occurred to me to convert to temperature as I had always worked with the thermistor calculated voltages. All my data for the Independence was derived by using a potentiometer on it and finding the transitions points and corresponding thermistor voltages. The state machine works off voltage thresholds. If I find the real characteristics of the thermistor, I will just build a new temperature table and change the voltage thresholds points in the program to reflect it.

> The benefit was that a 5°C temperature rise for combustion detection works at any temperature.

I'll give you that one, but the voltage changes at the normal ignition temperatures range are pretty large so it's never been a problem.

> That's the tank gas valve, in the warm up phase, no? The gas does not really stop for a while after

> shutting the tank valve. The electric valve is much quicker.

I was actually shutting it off using the electric valve in both cases, and so expected to see a faster response. Not only does it not decrease in temperature, it actually continues to rise for almost 2 mins before it starts to decrease. I will play with and monitor this more next year.

> It needs a weatherproof laminated guide to the blinking lights! And a warning label that it will start when

> plugged in.

Um, I'm not making a product here.. :) I'm the only person using these devices. And the LEDs are only the visual backup. The same data is available on the web interface in a more verbose manner.

> Still, it might be good to save the on/off state so that it persists during a power failure,

Yes, I will be using the EEPROM on the unit to store the last state so that it would power back up in that state. That's the more logical way to do it... I'm also going to add an ambient temperature sensor as I like having that to correlate to the chamber temperature.

It's been running very nicely for the last 2 days. Since I don't really have any mosquitoes left, I basically have it run two short propane cycles at dusk and dawn, just as a test. My igniter ramp cycles must be good enough as it's been working flawlessly so far. The real test will be next year when I run it that way for several months.

|

Use at own risk! September 29, 2020 07:30PM | Registered: 3 years ago Posts: 152 |

After thinking about it for a bit, I've decided to post the PCB files and code for this project. This is a hobby and information site, and obviously anything that anyone takes from it is at their own risk. However, I've gotten a lot of useful information from things people have posted over the years, and if anything that I've done is useful to someone else, then it's worth posting here. It's being posted with all the usual disclaimers, including it all being experimental and untested, so use at your own risk!

This isn't a step by step post. Quite frankly, if you are able to take any the information here and actually make something out of it, then you probably have enough expertise to have done it all yourself anyway. The information is posted here mostly to use as an example as you navigate your own journey. So, no comments about how many design rules the PCB layout breaks, or how badly written the source code is!

So, with that said, here are the Gerber files for the controller PCB. It is based on the Version 1.2 of the schematic posted before. I actually haven't used this particular version as I am on Version 1.1, but it should be fine. In order to procure the board, you basically upload the zip file to jlcpcb.com, pay them about $25, and in just about 7 days, 5 nice little PCBs will arrive at your front door via DHL.

The source code follows. As mentioned, it's developed under the Arduino IDE. It's not fully documented, but fundamentally the main loop is just a state machine that handles the various states. All other functions are handled by service routines that are called every pass through the main loop. The SSID/password as well as the mqtt broker information is set in the code and is essentially hard coded. All the code takes less than

60K of space, so there is plenty of available space. The code posted is version 1.1 and includes support for a BME280 temp/hum sensor. It also uses the Flash memory to store the ON/OFF state of the machine so it powers up in the last state it was in. I also took the opportunity to add a Gas run time counter. It basically counts days, hours, minutes when the gas solenoid is turned on. Because there is no real EEPROM on the Wemos D1 mini, I had to limit the number of times the Flash was written to. So, it only updates the Flash each time the solenoid turns off, or once a day, whichever comes first. In my case, I use two cycles a day, so the Flash is only written twice a day during the season. For those who run it continuously, if you loose power, you will loose up to one day of usage.

So, here is the experimental code, mistakes, bugs and all:

Edited 3 time(s). Last edit at 09/30/2020 01:43AM by Independence.

This isn't a step by step post. Quite frankly, if you are able to take any the information here and actually make something out of it, then you probably have enough expertise to have done it all yourself anyway. The information is posted here mostly to use as an example as you navigate your own journey. So, no comments about how many design rules the PCB layout breaks, or how badly written the source code is!

So, with that said, here are the Gerber files for the controller PCB. It is based on the Version 1.2 of the schematic posted before. I actually haven't used this particular version as I am on Version 1.1, but it should be fine. In order to procure the board, you basically upload the zip file to jlcpcb.com, pay them about $25, and in just about 7 days, 5 nice little PCBs will arrive at your front door via DHL.

The source code follows. As mentioned, it's developed under the Arduino IDE. It's not fully documented, but fundamentally the main loop is just a state machine that handles the various states. All other functions are handled by service routines that are called every pass through the main loop. The SSID/password as well as the mqtt broker information is set in the code and is essentially hard coded. All the code takes less than

60K of space, so there is plenty of available space. The code posted is version 1.1 and includes support for a BME280 temp/hum sensor. It also uses the Flash memory to store the ON/OFF state of the machine so it powers up in the last state it was in. I also took the opportunity to add a Gas run time counter. It basically counts days, hours, minutes when the gas solenoid is turned on. Because there is no real EEPROM on the Wemos D1 mini, I had to limit the number of times the Flash was written to. So, it only updates the Flash each time the solenoid turns off, or once a day, whichever comes first. In my case, I use two cycles a day, so the Flash is only written twice a day during the season. For those who run it continuously, if you loose power, you will loose up to one day of usage.

So, here is the experimental code, mistakes, bugs and all:

/*

* ESP8266 Wemos D1 mini controller for Experimentation

Failed states:

1 red blink - Failed to ignite

2 red blinks - Failed to reach operating temp in allocated time

3 red blinks - Under temperature

4 red blinks - Over temperature

5 red blinks - Low battery for AC (N/A)

Status LEDs based on Thermistor voltage:

Warmup mode - Yellow LED

Startup - Solid Yellow

Ignition Detected - 1 Blink Yellow

Various Voltages - 2-4 blinks

Run Mode - Green LED

Run to 1.8v - Solid Green

2.0v to 1.8v - 1 Blink

1.8v to 1.1v - 2 Blink

Cooldown Mode

5 blinks Yellow

Fan Mode

Alternate Green/Yellow

Ver 1.0 - 9/26/2020 - First version

Ver 1.1 - 9/29/2020 - Added temp/hum sensor, persistent ON/OFF state, and run time counter

*

*/

// Set the specific variables below first!!

//Define the client

#define CLIENT "Liberty1"

// Client specific configurations below

#define VERSION "V1.1 Sep 29th 2020 " CLIENT

#define URL "/"

#define CLIENTID "esp8266" CLIENT

//SSID and Password of your WiFi router

const char* ssid = "<Your SSID>";

const char* password = "<Your Password>";

//mqtt information

const char* mqttServer = "<your.mqtt.broker.com>";

const int mqttPort = 1883;

const char* mqttUser = "";

const char* mqttPassword = "";

#include <EEPROM.h>

#include <ESP8266WiFi.h>

#include <WiFiClient.h>

#include <PubSubClient.h>

#include <Wire.h>

#include <ESP8266WebServer.h>

#include<ADS1115_WE.h>

#include <SparkFunBME280.h>

BME280 mySensor;

#define I2C_ADDRESS 0x48

ADS1115_WE adc(I2C_ADDRESS);

#define ON 1

#define OFF 0

#define DISABLED 0

#define ENABLED 1

WiFiClient espClient;

PubSubClient client(espClient);

//Declare a global object variable from the ESP8266WebServer class.

ESP8266WebServer server(80); //Server on port 80

// Define the Wemos pin mappings

#define SOLENOID D8 // High turns on solenoid

#define IGNITOR D0 // High turns on ignitor - not sure about cadence yet

#define GREEN_LED D5 // Green LED - Low to turn on

#define RED_LED D4 // Red LED - Low to turn on

#define YEL_LED D6 // Yel LED

#define ADLOW D7 // Out high to set A/D lower mode - Set to input otherwise

#define FAN D3 // PWM pin for the fan

// MQTT related definitions and variables

#define MQTT_POLL 60000 // Amount of time between sending 1 min

#define CONNECT_TM 2000 // Check for connection every 2 secs

int mqtt_state;

unsigned long int mqtt_timer, connect_timer, mqtt_poll_time = MQTT_POLL;

//ADC Variables

float adc0, adc1, adc2;

int adc_state;

//Membrane Switch definitions and variables

// Voltage thresholds

#define NULL_HIGH 5.0

#define NULL_LOW 3.24

#define OFF_HIGH 3.24

#define OFF_LOW 1.95

#define ON_HIGH 1.95

#define ON_LOW 0.2

// Debounce time in ms

#define SW_DBNC_TM 300

byte switch_latch, on_sw_state, off_sw_state;

unsigned long int on_switch_timer, off_switch_timer;

//Thermistor definitions and variables

// Voltage thresholds for Thermistor

#define YEL_1BLNK 2.418 // 40C

#define YEL_2BLNK 1.791 // 60C

#define YEL_3BLNK 1.239 // 80C

#define YEL_4BLNK 2.649 // 90C in low ADC range

#define TH_GREEN 2.30 // Run mode

#define GREEN_1BLNK 2.0 // Higher temps thresholds

#define GREEN_2BLNK 1.8 //

#define TH_UNDER 2.6 // Under temperature

#define TH_OVER 1.1 // Over temperature

#define IGN_DETECT 0.1 // Ignition detect difference

// Define states of themistor

#define HIGHSTATE 0

#define TRANSLOW 1

#define TRANSHI 2

#define LOWSTATE 3

char *thermistor_states[] = {"High", ">Low", ">High", "Low"};

byte thermistor_state, thermistor_block, thermistor_cnt, thermistor_dbnc;

float thermistor, thermistor_pre, thermistor_temp;

unsigned long int thermistor_timer;

// Define LED states for servicing. Set via set_led(STATE, #blinks)

#define LEDOFF 0 // All LEDs off

#define LEDYELLOW 1 // Solid Yellow

#define LEDRED 2 // Solid Red

#define LEDGREEN 3 // Solid Green

#define YELBLNK 4 // Yellow with Off blinks

#define GREENBLNK 5 // Green with Off blinks

#define REDBLNK 6 // Red with On blinks

#define GREENYEL 7 // Alternate between

// Blink times, states, and variables

#define LED_BLNK_ON 300 // ms of ON blink time

#define LED_BLNK_OFF 300 // ms of OFF blink time

#define LED_BLNK_WT 3000 // Wait time between blinks

#define LED_BLNK_ALT 1000 // ms between alternating green/yell

// States

#define BLNK_START 0

#define BLNK_ON 1

#define BLNK_OFF 2

#define BLNK_PAUSE 3

byte led_state, led_blink_state, led_mode, led_blinks, led_blink_cnt;

unsigned long int led_timer;

// Define LED indicator states. Stored in led_mode to keep track of current mode so as not to set more than once

#define WARM1 1 // Warmup state 1, solid yellow

#define WARM2 2 // Yellow 1 blinks

#define WARM3 3 // Yellow 2 blinks

#define WARM4 4 // Yellow 3 blinks

#define WARM5 5 // Yellow 4 blinks

#define RUN1 6 // Run mode, solid green

#define RUN2 7 // Green 1 blink

#define RUN3 8 // Green 2 blink

// Ignitor slow ramp up definitions. PWM range is 0-1023 for esp8266

#define TIMEOUT 65000 // Total timeout before shutting off igniter. Starts when IGN turns on

#define RAMPTHRESH 400 // PWM Threshold value for RAMP2

#define RAMP2HOLD 2000 // How many ms to hold on ramp2 wait stage

#define RAMP1WAIT 200 // Ramp 1 increment time

#define RAMP2WAIT 400 // Ramp 3 increment time

#define INCREMENT 20 // How many PWM increments per time period

#define PWMZERO 0 // PWM goes between 0 (OFF) and 255 (FULL ON)

#define PWMFULL 1023

// Ignitor State machine States

#define START 0 // Start here and wait for changes

#define RAMP1 1 // First stage of ramp

#define RAMPHOLD 2 // Hold stage of ramp

#define RAMP2 3 // Final stage of ramp

#define OFFHOLD 4 // Force igniter off, regardless of input

int ignitor_state, pwm;

unsigned long int ignitor_ramp_timer, ignitor_timeout;

// Some timer values in ms

#define PURGE_TM 25000 // Amount of time to purge

#define TO_IGNITOR 000 // Before ignitor

#define PRE_GAS 000 // Ignitor on before gas

#define NO_IGNITE 240000 // Maximum time to wait for ignition 4 mins

#define NORUN 1800000 // Max wait till run mode 30 mins

// Fan PWM definitions, need to validate normal running speed

#define FAN_NORMAL 1023

#define FAN_FAST 920 // Cooldown fan speed

#define FAN_90 920 // 90% fan speed

#define FAN_80 818 // 80% fan speed

#define FAN_65 665 // 65%

#define FAN_FULL 1023

// States for the main running routine. Not all used in all versions

#define OFFSTATE 0 // Starting state, Switch is off

#define PURGE 1 // Purge state to clear out any gas

#define WAITSTART 2 // Wait a while before starting ignitor

#define IGNITE 3 // Start the ignitor

#define GASON 4 // Turn on gas

#define CKIGNITE 5 // Check for ignite

#define WARMUP 6 // Wait for running temperature

#define RUN 7 // Running mode

#define POWER_OFF 8

#define COOLDOWN 9

#define FAIL 10

#define DONOTHING 11

#define FANONLY 12

#define PRE_HIB 14

#define HIBERNATE 15 // Equivalent to OFF state with the switch ON. Power save mode set via remote interface

#define RUN_OVER 16 // These run states are only used to indicate conditions, not real states

#define RUN_UNDER 17

char *main_states[] = {"Off", "Purge", "Wait Ign", "Ignite", "Gas On", "Ck Ignite", "Warmup", "Run", "Power Off", "Cool Down", "Fail", "Do Nothing", "Fan Mode", "null", "Pre-Hib", "Hibernate"};

// Error codes, also corresponds to number of red blinks

#define NO_ERROR 0

#define NO_IGN 1

#define NO_TEMP 2

#define UNDER_TEMP 3

#define OVER_TEMP 4

#define LOW_BAT 5

#define UNKNOWN_ERROR 6

char *error_codes[] = {"None", "No Ignition", "Didn't reach temperature", "Under Temperature", "Over Temperature", "Low Battery", "Unknown Error"};

int error_code;

int main_state, next_state, previous_state, fan_speed, flag1, flag2, auto_print, terminal_flag;

int days, hours, mins, tracking_state, tempflag;

float temperature, humidity;

unsigned long int main_timer, ignitor_timer, temperature_timer, tracking_timer, eeprom_save_timer, temp_timer;

//----------------------------------

// End of definitions, start of code

//----------------------------------

// One time setup code

void setup(void){

EEPROM.begin(8);

pinMode(RED_LED, INPUT); digitalWrite(RED_LED, LOW); // All LEDs off

pinMode(GREEN_LED, INPUT); digitalWrite(GREEN_LED, LOW);

pinMode(YEL_LED, INPUT); digitalWrite(YEL_LED, LOW);

analogWrite(FAN, 0); pinMode(FAN, OUTPUT); // Fan off

analogWrite(IGNITOR, 0); pinMode(IGNITOR, OUTPUT); // Ignitor off

pinMode(SOLENOID, OUTPUT); digitalWrite(SOLENOID, LOW); // Gas Solenoid off

pinMode(ADLOW, INPUT);digitalWrite(ADLOW, HIGH); // Disable low range of ADC

Serial.begin(115200);

WiFi.begin(ssid, password); //Connect to your WiFi router

Serial.println("");

// Wait for connection

while (WiFi.status() != WL_CONNECTED) {

delay(500);

Serial.print(".");

}

//If connection successful show IP address in serial monitor

Serial.println("");

Serial.print("Connected to ");

Serial.println(ssid);

Serial.print("IP address: ");

Serial.println(WiFi.localIP()); //IP address assigned to your ESP

// Set up the web server handler routines for each URL

server.on("/", handleRoot); //Which routine to handle at root location. This is main display page

server.on("/normal", normal); // Send normal command

server.on("/fan", fan); // Send fan command

server.on("/hibernate", hibernate); // Send hibernate command

server.on("/mqtt", mqtt); // Toggle mqtt state

server.on("/decmqtt", decmqtt); // Decrease mqtt time

server.on("/resrun", resrun); // Reset run counter

server.on("/optiona", optiona); // Send options

server.on("/optionb", optionb); // Send options

server.on("/optionc", optionc); // Send options

server.on("/optiond", optiond); // Send options

server.begin(); //Start server

Serial.println("HTTP server started");

Wire.begin(); // Start i2c and initialize devices

// Setup address of temp sensor

mySensor.setI2CAddress(0x76);

if (mySensor.beginI2C() == false) //Begin communication over I2C

{

Serial.println("BME280 temp sensor did not respond");

}

// Setup and start the ADC via i2c

if(!adc.init()){

Serial.println("ADS1115 not connected!");

}

adc.setVoltageRange_mV(ADS1115_RANGE_6144);

adc.setCompareChannels(ADS1115_COMP_0_GND);

adc.startSingleMeasurement(); // Kick off first measurement; it is read in arrears and non-blocking mode as part of service_adc() routine

// Setup MQTT

client.setServer(mqttServer, mqttPort);

mqtt_timer = connect_timer = millis();

// Take care of other initializations

main_timer = on_switch_timer = off_switch_timer = thermistor_timer = temperature_timer = millis();

main_state = adc_state = thermistor_state = 0;

if (EEPROM.read(1) != OFF) {

on_sw_state = ON; // Force the unit to come on by spoofing the ON switch

}

days = EEPROM.read(2); // Recover the current gas runtime

hours = EEPROM.read(3);

mins = EEPROM.read(4);

}

//----------------------------

// Main code loop starts here

//----------------------------

void loop(void){

// Service all the ancillary functions. Should all be non-blocking

server.handleClient(); //Handle web client requests

service_adc();

service_switches();

service_thermistor();

service_led();

service_mqtt();

service_temperature();

track_runtime();

service_terminal(); // Console may be removed for production

// Now service the main state machine

switch (main_state) {

case OFFSTATE: // Comes here when off to wait for ON button or Wifi control

if (off_sw_state == ON)

off_sw_state = OFF; // Ignore off switch here

if (on_sw_state == ON) {

set_on(); // Save the state

on_sw_state = OFF;

analogWrite(FAN, FAN_FULL); // High Fan

fan_speed = FAN_FULL;

set_led(LEDYELLOW,0);

pinMode(ADLOW, INPUT); // Reset the thermistor range

thermistor_state = HIGHSTATE;

main_timer = millis();

main_state = PURGE;

Serial.println("Entering purge state..");

}

break;

case HIBERNATE: // This is essentially an OFF state, waits for ON button or Wifi control

if (off_sw_state == ON)

off_sw_state = OFF; // Ignore off switch here

if (on_sw_state == ON) { // Don't reset switch state so it will continue to power on from OFFSTATE

main_timer = millis();

main_state = OFFSTATE;

Serial.println("Exiting Hibernate state..");

}

break;

case PURGE: // Runs fan at full speed to purge chamber of all gas

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

off_sw_state = OFF;

main_state = POWER_OFF;

}

if (millis() - main_timer >= PURGE_TM ) { // After purge time, go wait, if necessary, before starting

analogWrite(FAN, FAN_FULL);

fan_speed = FAN_FULL;

main_timer = millis();

main_state = WAITSTART;

Serial.println("Entering wait start..");

}

break;

case WAITSTART: // Comes here to wait for TO_IGNITOR time and thermistor to be in HIGHSTATE (cool)

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

off_sw_state = OFF;

main_state = POWER_OFF;

}

if (millis() - main_timer >= TO_IGNITOR && thermistor_state == HIGHSTATE) { // If all conditions met, proceed to ignition

analogWrite(FAN, FAN_NORMAL);

fan_speed = FAN_NORMAL;

main_timer = ignitor_timer = millis();

ignitor_state = START;

main_state = IGNITE;

Serial.println("Ignitor turned on..");

}

break;

case IGNITE: // Start the ignition process

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

off_sw_state = OFF;

main_state = POWER_OFF;

}

service_ignitor(); // Only serviced here and in GASON. Starts ramping up the ignitor PWM values

if (millis() - main_timer >= PRE_GAS ) { // Wait to turn on gas (for Independence). For Liberty, PRE_GAS = 0, no wait.

main_timer = ignitor_timer = millis();

digitalWrite(SOLENOID, HIGH);

main_state = GASON;

thermistor_pre = thermistor; // Save current value to check against for ignition

Serial.println("Gas turned on..");

}

break;

case GASON: // Gas turned on, check for ignition or failure to ignite

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

off_sw_state = OFF;

main_state = POWER_OFF;

}

service_ignitor(); // Ignitor should turn off automatically around this time...

if (thermistor_pre - thermistor > IGN_DETECT ) { // If voltage is dropping, then we have ignition

main_timer = millis();

digitalWrite(IGNITOR, LOW); // Ignitor should time out in service_ignitor(), but shut it off just in case

ignitor_state = OFFHOLD;

analogWrite(FAN, FAN_NORMAL); // Set fan to normal speed

fan_speed = FAN_NORMAL;

main_state = WARMUP;

set_led(YELBLNK,1);

Serial.print(thermistor);

Serial.println(" Gas ignited, proceeding to warmup");

}

if (millis() - main_timer >= NO_IGNITE) { // If we time out here, that means we didn't get ignition, so error out

previous_state = GASON;

main_state = FAIL;

}

break;

case WARMUP: // This is the main warm up state, just check for operating temperatures, or timeout

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

off_sw_state = OFF;

next_state = POWER_OFF;

main_state = COOLDOWN;

set_led(YELBLNK,5);

Serial.println("Cooling down before power off..");

}

if (thermistor_state == LOWSTATE) { // Should be in low ADC state to check for RUN mode.

if (thermistor <= TH_GREEN && thermistor_block == OFF) {

main_timer = millis();

main_state = RUN;

set_led(LEDGREEN,0);

Serial.print(thermistor);

Serial.println(" Proceeding to run state");

}

if ( thermistor <= YEL_4BLNK && thermistor > TH_GREEN && led_mode != WARM5 ) {

led_mode = WARM5;

set_led(YELBLNK,4);

}

}

else {

if ( thermistor <= YEL_1BLNK && thermistor > YEL_2BLNK && led_mode != WARM2 ) {

led_mode = WARM2;

set_led(YELBLNK,1);

}

if ( thermistor <= YEL_2BLNK && thermistor > YEL_3BLNK && led_mode != WARM3 ) {

led_mode = WARM3;

set_led(YELBLNK,2);

}

if ( thermistor <= YEL_3BLNK && thermistor > 1.1 && led_mode != WARM4 ) {

led_mode = WARM4;

set_led(YELBLNK,3);

}

}

if (millis() - main_timer >= NORUN) { // Error out if we timed out and never made it to Run temperatures...

previous_state = WARMUP;

main_state = FAIL;

}

break;

case RUN: // We are now in normal operating mode, just check for over and under temps

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

off_sw_state = OFF;

next_state = POWER_OFF;

main_state = COOLDOWN;

set_led(YELBLNK, 5);

Serial.println("Cooldown before power off..");

}

if (thermistor < TH_OVER ) {

previous_state = RUN_OVER;

main_state = FAIL;

}

if (thermistor >= TH_UNDER) {

previous_state = RUN_UNDER;

main_state = FAIL;

}

// Monitor the temps and set the Green LED appropriately

if ( thermistor <= TH_GREEN && thermistor > GREEN_1BLNK && led_mode != RUN1 ) {

led_mode = RUN1;

set_led(LEDGREEN,0);

}

if ( thermistor <= GREEN_1BLNK && thermistor > GREEN_2BLNK && led_mode != RUN2 ) {

led_mode = RUN2;

set_led(GREENBLNK,1);

}

if ( thermistor <= GREEN_2BLNK && thermistor > TH_OVER && led_mode != RUN3 ) {

led_mode = RUN3;

set_led(GREENBLNK,2);

}

break;

case FAIL: // Comes here on error, turn off gas and set the error LEDs and error codes

digitalWrite(SOLENOID, LOW);

digitalWrite(IGNITOR, LOW);

ignitor_state = OFFHOLD;

if (thermistor_state == HIGHSTATE) { // Don't shut off fan until thermistor is in high state

analogWrite(FAN, 0);

fan_speed = 0;

}

else {

analogWrite(FAN, FAN_NORMAL);

fan_speed = FAN_NORMAL;

}

if (previous_state == GASON) {

set_led(REDBLNK, 1);

error_code = NO_IGN;

}

else if (previous_state == WARMUP) {

set_led(REDBLNK, 2);

error_code = NO_TEMP;

}

else if (previous_state == RUN_UNDER) {

set_led(REDBLNK, 3);

error_code = UNDER_TEMP;

}

else if (previous_state == RUN_OVER) {

set_led(REDBLNK, 4);

error_code = OVER_TEMP;

}

else if (previous_state == FANONLY) { // Can only be from low battery, only for Independence

set_led(REDBLNK, 5);

error_code = LOW_BAT;

}

else {

set_led(REDBLNK, 10);

error_code = UNKNOWN_ERROR;

}

Serial.print("Something failed, error code = ");

Serial.println(error_codes[error_code]);

main_state = DONOTHING;

break;

case DONOTHING: // Just sit here, blink LEDs and keep fan on till cooled down

if (on_sw_state == ON)

on_sw_state = OFF; // Ignore on switch here

if (off_sw_state == ON) {

next_state = POWER_OFF;

main_state = COOLDOWN;

set_led(YELBLNK, 5);

error_code = NO_ERROR;

Serial.println("Cooldown before power off..");

}

if (thermistor_state == HIGHSTATE) {

analogWrite(FAN, 0);

fan_speed = 0;

}

else {

analogWrite(FAN, FAN_NORMAL);

fan_speed = FAN_NORMAL;

}

break;

case COOLDOWN: // This is cooldown state before powering off or hibernating

if (on_sw_state || off_sw_state)

on_sw_state = off_sw_state = OFF; // Ignore both switches here

analogWrite(FAN, FAN_FAST);

fan_speed = FAN_FAST;

digitalWrite(SOLENOID, LOW);

if (thermistor_state == HIGHSTATE) {

main_state = next_state;

set_led(LEDOFF,0); // Either going to OFF or HIBERNATE

}

break;

case FANONLY: // Comes here to keep fan on but no gas. Keeps mosquitoes in the net till they die

if (on_sw_state == ON) { // Don't reset switch so it will power on normally from OFF state

next_state = POWER_OFF;

main_state = COOLDOWN;

set_led(YELBLNK, 5);

Serial.println("Cooldown before re-powering..");

}

if (off_sw_state == ON) {

off_sw_state = OFF;

next_state = POWER_OFF;

main_state = COOLDOWN;

set_led(YELBLNK, 5);

Serial.println("Cooldown before power off..");

}