Home

>

Mosquito Magnet

>

Topic

MM Pro 1000mm

Posted by biofuelin

|

MM Pro 1000mm July 14, 2020 04:34PM | Registered: 3 years ago Posts: 5 |

|

Re: MM Pro 1000mm July 14, 2020 10:04PM | Registered: 3 years ago Posts: 152 |

Welcome! I certainly don't have any experience with it, but you can read the other threads here to get an idea of how the other units work. Fundamentally, they all work on the same premise, with maybe some variations in the implementation.

Maybe you can post what you do know and what issues you're having, and see if other folks on here can offer any suggestions?

Maybe you can post what you do know and what issues you're having, and see if other folks on here can offer any suggestions?

|

Re: MM Pro 1000mm July 16, 2020 04:26AM | Registered: 3 years ago Posts: 5 |

Today I have a unit operating in my yard that has 2 new fans, 4 new TEG modules wired in series and installed on a heat sink that is flat to +- 0.001 with a surface prep of 20 micro inches. I also sourced a small quantity of the catalytic beads from the manufacturer, so my machine has 12g of new product in it. Of course the propane regulator was replaced with a Goss adjustable model and the propane nozzle is clean.

After all of this I have a couple problems. First, I am not getting good heat transfer even after using graphite sheets as a thermal interface material. Low ΔT results in a low voltage production and slow fans. My second issue has to do with the catalytic burner. I don't know how many grams of catalytic beads to use, so I put 12g in this one (has to be close). A related problem has to do with the adjustment screw on the nozzle housing. I'm not getting a proper catalytic reaction due to improper air flow/adjustment.

I have repaired a few of this model in the past, but this is my first complete rebuild. Any constructive ideas would be appreciated. I have about 50 photos of the disassembly and rebuild process, but can't seem to upload them on this forum. More to come regarding pics.

thanks

After all of this I have a couple problems. First, I am not getting good heat transfer even after using graphite sheets as a thermal interface material. Low ΔT results in a low voltage production and slow fans. My second issue has to do with the catalytic burner. I don't know how many grams of catalytic beads to use, so I put 12g in this one (has to be close). A related problem has to do with the adjustment screw on the nozzle housing. I'm not getting a proper catalytic reaction due to improper air flow/adjustment.

I have repaired a few of this model in the past, but this is my first complete rebuild. Any constructive ideas would be appreciated. I have about 50 photos of the disassembly and rebuild process, but can't seem to upload them on this forum. More to come regarding pics.

thanks

|

Re: MM Pro 1000mm July 16, 2020 02:03PM | Registered: 3 years ago Posts: 152 |

Both the low voltage on the TEGs and the catalytic reaction could be due to low temperatures in the burner. Do you know what temperature it is supposed to be operating at? On the Independence, which also has the TEGs, the temperature of the catalytic converter appears to about 160-180 C during operation, though the TEGs come up to voltage around 80C.

-

-

|

Combustion Temperature and Mixture July 19, 2020 07:01PM | Admin Registered: 7 years ago Posts: 164 |

I agree that the low ΔT might be from too low combustion temperature. What temperature does the sensor read? Or, what is your best estimate of the interior temperature?

On the Defender, temps in the flow just after the catalyst are about 85°C to 90°C above ambient. So, now on a hot day, the thermistor indicates 128.4C with an ambient of 44.5C and relative humidity of 23.5% (it's hot today). The temps are above ambient because the complete combustion adds a certain amount of heat to a known lean propane and air mixture. The propane flow is fixed, air is supposed to be significantly more than enough.

I believe the mixture is lean because the designers required complete combustion, as the patent application(s) state that both unburned propane and carbon monoxide are mosquito repellents. The patent(s) also state that the catalyst is used to complete oxidation of any carbon monoxide to carbon dioxide. Prior to reading the patents, I had thought that the process was like an old fashioned lighter fluid hand warmer that used "platinized asbestos" as a catalyst to provide a low heat without flame, but no, apparently this is not the case.

So, a few things stand out. First, the only "Goss adjustable" regulators I could find on the www were 0-30 psi high pressure units, but the trap is a low pressure application. The Defender, Liberty, and Patriot use standard 11 inch water column fixed pressure regulators. See the blog for more on this. You may be feeding too much propane, and the regulation may not be very repeatable or accurate at low pressures. What is used on the Pro models?

...the adjustment screw on the nozzle housing. I'm not getting a proper catalytic reaction due to improper air flow/adjustment.

What does this screw do? Adjust the air, or the propane? I don't know about the Pro model. Can you give more information?

BTW, you should be able to insert pictures into your posts. What errors did you get? I noticed that the forum had a smallish 1000 kB upload file size limit, I just changed that to 2000 kB (~2 mB). PM me if you are having trouble.

Here is my Defender a few minutes ago:

Temp=128.4C (0) at 5:204732 F=1 I=0 G=1 S=1 E=0 T=44.5C H=23.5% M=8760 (204/1011:4758) R=70~140 W=-80 B=1.0 V=3.4

Edited 1 time(s). Last edit at 07/20/2020 01:43AM by dev.

On the Defender, temps in the flow just after the catalyst are about 85°C to 90°C above ambient. So, now on a hot day, the thermistor indicates 128.4C with an ambient of 44.5C and relative humidity of 23.5% (it's hot today). The temps are above ambient because the complete combustion adds a certain amount of heat to a known lean propane and air mixture. The propane flow is fixed, air is supposed to be significantly more than enough.

I believe the mixture is lean because the designers required complete combustion, as the patent application(s) state that both unburned propane and carbon monoxide are mosquito repellents. The patent(s) also state that the catalyst is used to complete oxidation of any carbon monoxide to carbon dioxide. Prior to reading the patents, I had thought that the process was like an old fashioned lighter fluid hand warmer that used "platinized asbestos" as a catalyst to provide a low heat without flame, but no, apparently this is not the case.

So, a few things stand out. First, the only "Goss adjustable" regulators I could find on the www were 0-30 psi high pressure units, but the trap is a low pressure application. The Defender, Liberty, and Patriot use standard 11 inch water column fixed pressure regulators. See the blog for more on this. You may be feeding too much propane, and the regulation may not be very repeatable or accurate at low pressures. What is used on the Pro models?

...the adjustment screw on the nozzle housing. I'm not getting a proper catalytic reaction due to improper air flow/adjustment.

What does this screw do? Adjust the air, or the propane? I don't know about the Pro model. Can you give more information?

BTW, you should be able to insert pictures into your posts. What errors did you get? I noticed that the forum had a smallish 1000 kB upload file size limit, I just changed that to 2000 kB (~2 mB). PM me if you are having trouble.

Here is my Defender a few minutes ago:

Temp=128.4C (0) at 5:204732 F=1 I=0 G=1 S=1 E=0 T=44.5C H=23.5% M=8760 (204/1011:4758) R=70~140 W=-80 B=1.0 V=3.4

Edited 1 time(s). Last edit at 07/20/2020 01:43AM by dev.

|

Re: Combustion Temperature and Mixture July 22, 2020 12:22AM | Registered: 3 years ago Posts: 8 |

I've been reading with interest all the forum messages, and thought I'd chip in here since I also have a MM1000 Commercial Pro. It might be instructive to read one of the original patents - 6,145,243 - you can download a PDF of it from that Google link. In it, we find that the diagram appears to be that of the MM1000 Commercial Pro. Also, it turns out this is an analog system - no microprocessor. I find this interesting since this ancient machine is the only one that really works reliably - my others (2x Liberty, 1x Defender) all wind up having recurring issues of one kind or another - but that's a topic for a different post. Since the Commercial Pro has an analog control system, I think comparing the Defender, Liberty, etc. operations may be hard to do. There are some interesting things mentioned in the patent:

"The attractant exhaust System can be structured and arranged to release the insect attractant with a CO concentration in a range between about 500 ppm and about 2500 ppm, or, more preferably for attracting mosquitos that prey on humans, with a CO concentration in a range between about 1200 ppm and about 1800 ppm. The combustor can be Structured and arranged to provide CO gas at a rate of about 300 ml/min to about 500 ml/min."

also:

"...providing a mixture that includes CO2 gas and air, and releasing the mixture near the trap inlet at a temperature above ambient temperature and below about 115 F. "

So that's some useful info.

A note on the TEG: The original is a high temperature version (Melcor HT6-7-30-T1 - now Laird ) - high temperature version use different solder among other things. You didn't mention what TEG units were used- it would be great if you were able to source original replacement types. Also, TEGs are not just TECs (coolers) used in reverse. Unfortunately it's not quite that simple :(

There is alot more good info in the patent. On the 10th page, column 7 and column 8, it talks about the TEG, the power supply, voltages fed to the system and fans, etc. and some adjustment info. Too much to go into here I think, but this should give you some good trouble shooting info. My particular unit seems to run a little cool, the temp gauge is in the blue, but points to about 4 oclock. I don't know if that's normal or if I should expect it to be higher. So I'll probably be digging into mine a bit and looking into what those levels are myself.

"The attractant exhaust System can be structured and arranged to release the insect attractant with a CO concentration in a range between about 500 ppm and about 2500 ppm, or, more preferably for attracting mosquitos that prey on humans, with a CO concentration in a range between about 1200 ppm and about 1800 ppm. The combustor can be Structured and arranged to provide CO gas at a rate of about 300 ml/min to about 500 ml/min."

also:

"...providing a mixture that includes CO2 gas and air, and releasing the mixture near the trap inlet at a temperature above ambient temperature and below about 115 F. "

So that's some useful info.

A note on the TEG: The original is a high temperature version (Melcor HT6-7-30-T1 - now Laird ) - high temperature version use different solder among other things. You didn't mention what TEG units were used- it would be great if you were able to source original replacement types. Also, TEGs are not just TECs (coolers) used in reverse. Unfortunately it's not quite that simple :(

There is alot more good info in the patent. On the 10th page, column 7 and column 8, it talks about the TEG, the power supply, voltages fed to the system and fans, etc. and some adjustment info. Too much to go into here I think, but this should give you some good trouble shooting info. My particular unit seems to run a little cool, the temp gauge is in the blue, but points to about 4 oclock. I don't know if that's normal or if I should expect it to be higher. So I'll probably be digging into mine a bit and looking into what those levels are myself.

|

Re: Combustion Temperature and Mixture July 26, 2020 01:53AM | Registered: 3 years ago Posts: 8 |

A quick update: After doing some testing on my Commercial Pro, it seems that it is indeed running cold. The TEG is only putting out a bit more than 7 volts. This is enough to turn on the suction fan (rated 5V), but not enough to turn on the exhaust fan (rated 12V). I put a thermocouple on the burn chamber, and it was around 155C. The heatsink side was around 60C. Plenty of delta T so the TEG should have been doing better.

So going on to further disassembly, this unit is even simpler than I thought. There are no electronics in it at all - not like what's shown in the patent. The TEG directly drives the fans, and that's it. But why is it running cold? It turns out this unit is kind of a basket case. At least one TEG is bad and at least half the catalyst beads in the chamber are cracked and split, with other corrosion mixed in. Plenty of other corrosion too of course, the thermal chamber screens are clogged, etc.

I seem to have tracked down a replacement for the TEG at Custom ThermoElectric but they're $30 each, and it takes three. You also need the interface material, and I'd have to try to replace the beads. With that cost, and multiple units available locally for $150, I'm calling this one 'uneconomical to repair'.

Sorry I don't have anything more to add on the Commercial Pro right now.

So going on to further disassembly, this unit is even simpler than I thought. There are no electronics in it at all - not like what's shown in the patent. The TEG directly drives the fans, and that's it. But why is it running cold? It turns out this unit is kind of a basket case. At least one TEG is bad and at least half the catalyst beads in the chamber are cracked and split, with other corrosion mixed in. Plenty of other corrosion too of course, the thermal chamber screens are clogged, etc.

I seem to have tracked down a replacement for the TEG at Custom ThermoElectric but they're $30 each, and it takes three. You also need the interface material, and I'd have to try to replace the beads. With that cost, and multiple units available locally for $150, I'm calling this one 'uneconomical to repair'.

Sorry I don't have anything more to add on the Commercial Pro right now.

|

Re: Combustion Temperature and Mixture July 27, 2020 04:11PM | Admin Registered: 7 years ago Posts: 164 |

I put a thermocouple on the burn chamber, and it was around 155C

That sounds quite hot. The Defender is running at 125°, or about 82°C above ambient of 43°C at about 4" from the burn point, after the catalytic converter. Perhaps yours is actually doing a catalytic conversion, unlike the Defender, which has a combustion chamber area where the flame is or could be, followed by about 4" cylinder with catalyst mesh. Are you running 11 inches-water column propane pressure into the system?

At any rate, the goal is complete combustion, so flame or catalytic, all the energy in the propane should be converted into heat, so the temperature rise should be the same, no? I have the Defender set to trip an overheat error above 140°C, although this is again about 4" away from the hottest part of the combustion flow.

Are the catalyst beads cracked and split affecting their performance, or the quality of the burn? Is there carbon monoxide exhaust from the trap? If not, perhaps you don't need to worry about the catalyst or the partially clogged screens.

Regarding the Custom ThermoElectric 12711-9L31-05CL Thermoelectric/Peltier Module, I looked at the spec sheet and could not determine its performance as a generator, the specs seemed to be for cooling. Did you look on Amazon Hilitand Thermoelectric Peltier Module or similar? For about $8 each, the web page specs "80 Degree Temperature Difference: Open Circuit Voltage 3.6V, Generated Current: 558MA," so 3 or 4 of these in series may do the trick. But I don't know anything about these gadgets. How did you choose the one you did? The part seems awfully expensive for a small piece of plastic. This seems like a fantastic hi-spec part, but we are not the DOD.

I suppose the purpose of the "interface material" is to insulate the generator from the metal chamber and heat sink so they can be wired in series. But it looks like the ceramic material on the TEG mentioned above is non-conductive, and does not require insulation. They have a picture of 12 of these wired in 4x3 series-parallel, and I could not see any additional insulators on what looks like a metal plate.

Perhaps I need to see some photos to understand what is going on.

Recent Defender:

Temp=125.3C (0) at 5:29093 F=1 I=0 G=1 S=1 E=0 T=42.5C H=28.4% M=6760 (218/1011:5175) R=70~140 W=-78 B=0.26 V=3.4

That sounds quite hot. The Defender is running at 125°, or about 82°C above ambient of 43°C at about 4" from the burn point, after the catalytic converter. Perhaps yours is actually doing a catalytic conversion, unlike the Defender, which has a combustion chamber area where the flame is or could be, followed by about 4" cylinder with catalyst mesh. Are you running 11 inches-water column propane pressure into the system?

At any rate, the goal is complete combustion, so flame or catalytic, all the energy in the propane should be converted into heat, so the temperature rise should be the same, no? I have the Defender set to trip an overheat error above 140°C, although this is again about 4" away from the hottest part of the combustion flow.

Are the catalyst beads cracked and split affecting their performance, or the quality of the burn? Is there carbon monoxide exhaust from the trap? If not, perhaps you don't need to worry about the catalyst or the partially clogged screens.

Regarding the Custom ThermoElectric 12711-9L31-05CL Thermoelectric/Peltier Module, I looked at the spec sheet and could not determine its performance as a generator, the specs seemed to be for cooling. Did you look on Amazon Hilitand Thermoelectric Peltier Module or similar? For about $8 each, the web page specs "80 Degree Temperature Difference: Open Circuit Voltage 3.6V, Generated Current: 558MA," so 3 or 4 of these in series may do the trick. But I don't know anything about these gadgets. How did you choose the one you did? The part seems awfully expensive for a small piece of plastic. This seems like a fantastic hi-spec part, but we are not the DOD.

I suppose the purpose of the "interface material" is to insulate the generator from the metal chamber and heat sink so they can be wired in series. But it looks like the ceramic material on the TEG mentioned above is non-conductive, and does not require insulation. They have a picture of 12 of these wired in 4x3 series-parallel, and I could not see any additional insulators on what looks like a metal plate.

Perhaps I need to see some photos to understand what is going on.

Recent Defender:

Temp=125.3C (0) at 5:29093 F=1 I=0 G=1 S=1 E=0 T=42.5C H=28.4% M=6760 (218/1011:5175) R=70~140 W=-78 B=0.26 V=3.4

|

Re: MM Pro 1000mm July 28, 2020 03:19AM | Registered: 3 years ago Posts: 152 |

With regards to those Amazon Hilitand TEGs, those are the exact same units I got from ebay for my Independence and they do not generate as much power as the OEM ones. A quick test shows that when I disconnect the battery power while in operating mode, the LEDs dim and the fan slows. In the case of my Independence, operating mode consumes about 700ma and if these TEGs can only produce about 500ma, that would explain it. When I get a chance, I will measure the actual voltage and current produced.

|

Re: Combustion Temperature and Mixture July 28, 2020 04:51PM | Registered: 3 years ago Posts: 8 |

The temperature did seem to be a bit high, but within the supposed limits of the TEG so I was not *too* concerned. Also, since the exhaust fan was not running, I expect the temperature was higher than it should be.

This model does perform a catalytic reaction, so I guess it was working - to a point anyway. Construction is that of an orifice in a tube with an air bleed, going into a box. The box has a screen near the bottom, and near the top, between which is a supply of catalyst beads. There is also a series of rods connected to the TEG side of the box to assist with heat transfer. (This is all shown in the patent.) There was a lot of 'sand' in the mix of beads in the chamber (corrosion products and bead fragments) clogging the upward path of the gas through the box. Not that many of the beads were intact - possibly a result of overheating? They would need to be replaced in any case.

With respect to the TEG: The model I mentioned was obtained from the old jmanley site on archive.org. There is definitely a focus on cooling as opposed to generation with these devices. If you do some research, you'll find that while TEC/TEG are to a degree interchangeable, there are definite differences in construction (and efficiency) between the two. I suppose at $8 or $10 one could experiment with the Amazon devices. Mine appeared dead after disassembly - significant corrosion internally.

They don't need electrical insulation, no. The interface material is a graphite with embedded mesh - they probably used this material as it has a very high working temperature (up to 200C). After looking around more, I can find non-silicone compounds that say they are good to 200C as well, so maybe I'll keep that in mind.

If I can get new beads, maybe I'll try resurrecting it. Even worst case I can put a wall wart on it and turn it into a plug-in model and not bother with the TEG.

This model does perform a catalytic reaction, so I guess it was working - to a point anyway. Construction is that of an orifice in a tube with an air bleed, going into a box. The box has a screen near the bottom, and near the top, between which is a supply of catalyst beads. There is also a series of rods connected to the TEG side of the box to assist with heat transfer. (This is all shown in the patent.) There was a lot of 'sand' in the mix of beads in the chamber (corrosion products and bead fragments) clogging the upward path of the gas through the box. Not that many of the beads were intact - possibly a result of overheating? They would need to be replaced in any case.

With respect to the TEG: The model I mentioned was obtained from the old jmanley site on archive.org. There is definitely a focus on cooling as opposed to generation with these devices. If you do some research, you'll find that while TEC/TEG are to a degree interchangeable, there are definite differences in construction (and efficiency) between the two. I suppose at $8 or $10 one could experiment with the Amazon devices. Mine appeared dead after disassembly - significant corrosion internally.

They don't need electrical insulation, no. The interface material is a graphite with embedded mesh - they probably used this material as it has a very high working temperature (up to 200C). After looking around more, I can find non-silicone compounds that say they are good to 200C as well, so maybe I'll keep that in mind.

If I can get new beads, maybe I'll try resurrecting it. Even worst case I can put a wall wart on it and turn it into a plug-in model and not bother with the TEG.

|

Re: MM Pro 1000mm July 28, 2020 05:47PM | Registered: 3 years ago Posts: 5 |

My pro currently has an internal operating temperature of about 145C which is just inside the blue zone. Externally I have a temp of 113C on the burner and 46C on the heat exchanger near the burner. Maybe the thermocouple isn't allowing proper pressure to the burner? Maybe the filter is obstructing flow? Tonight I will bypass the safety stuff just to see if it comes up to full operating temp (around 200C internal).

|

Re: MM Pro 1000mm August 01, 2020 01:39PM | Registered: 3 years ago Posts: 5 |

UPDATE:

Running a copper line from the regulator directly to the nozzle didn't change the operating temperature, and I switched out a couple different nozzles. Independence, regarding your question about normal operating temperature for the Pro model, 180C appears to be the low end of the operating spectrum. with around 205C near the higher end. This seems to be in line with Dev's comment

"temps in the flow just after the catalyst are about 85°C to 90°C above ambient."

Also, regarding the question about regulator pressure, the Pro model works at a higher pressure than other machines. Typically a working machine will have a regulator putting out 10-12 psi, however patent info states 15 psi is needed.

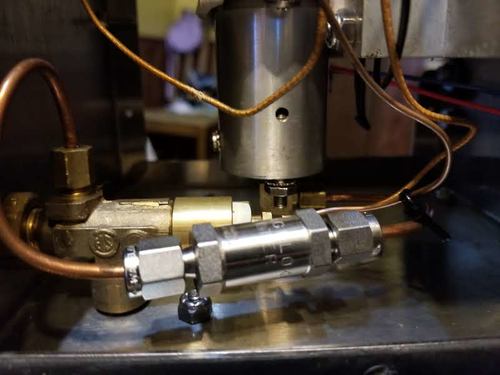

Below is a photo of the "carburetor" which shows the air mixture screw. The propane flow is set by the regulator in combination with the size of the nozzle aperture

I am stumped as to why my temp is still too low. I even changed thermometers just to be sure.

Thanks for all your input. OBVIOUSLY, I'm missing something.

Running a copper line from the regulator directly to the nozzle didn't change the operating temperature, and I switched out a couple different nozzles. Independence, regarding your question about normal operating temperature for the Pro model, 180C appears to be the low end of the operating spectrum. with around 205C near the higher end. This seems to be in line with Dev's comment

"temps in the flow just after the catalyst are about 85°C to 90°C above ambient."

Also, regarding the question about regulator pressure, the Pro model works at a higher pressure than other machines. Typically a working machine will have a regulator putting out 10-12 psi, however patent info states 15 psi is needed.

Below is a photo of the "carburetor" which shows the air mixture screw. The propane flow is set by the regulator in combination with the size of the nozzle aperture

I am stumped as to why my temp is still too low. I even changed thermometers just to be sure.

Thanks for all your input. OBVIOUSLY, I'm missing something.

|

Temperature Too Low August 01, 2020 05:37PM | Admin Registered: 7 years ago Posts: 164 |

...10-12 psi, however patent info states 15 psi is needed.

I have not been able to find a reference to these pressures. I looked at 6286249 (Sep. 17, 1996), 7243458 (Mar. 23, 2004), and 7752803 B2 (Jul. 13, 2010), which seem to be relevant. What is the patent number that has that info?

I wonder about your high-pressure regulator. I looked up the MM Pro 1000mm, and saw pictures of a rather ordinary-looking low pressure (11 inWC) regulator,

and compared it to the standard propane grill units used on the consumer Mosquito Magnets:

Except for the color, these look basically the same to me. Also, the MM Pro 1000mm product description says that the unit runs for about 21 days on a 20# tank, the same as the other models that use standard a low pressure regulator.

Running a copper line from the regulator directly to the nozzle didn't change the operating temperature

Perhaps the propane flow is way too high. This would cause too-low temperatures. Do you smell propane in the exhaust?

Regarding your picture, I don't understand the "air mixture screw." There appear to be two cylinders in the photo, one vertical, and one horizontal with copper lines on both sides. What is that device? Could it be a (clogged) fuel filter? I see what could be a screw coming out of the bottom of the horizontal cylinder. If it is a screw, perhaps it constricts the gas flow, and adjusts the rate of propane going into the chamber, much like the tiny holes in a nozzle. Because the air flow is fixed, this would adjust the mixture. When you said you bypassed the

I hope you didn't mean the screw-like thing that looks like a fitting coming out the bottom of the vertical unit (the burner?), I have no idea what that is. I guess I need another photo.

On another matter, I saw a troubleshooting page that recommended periodically shaking the unit to redistribute the catalyst beads. It also has a nice picture suggesting a proper bead quantity.

I'm really glad that we don't have to shake our consumer units (although my 1 year old Patriot has just stopped working, I guess I actually would like to shake it).

I have not been able to find a reference to these pressures. I looked at 6286249 (Sep. 17, 1996), 7243458 (Mar. 23, 2004), and 7752803 B2 (Jul. 13, 2010), which seem to be relevant. What is the patent number that has that info?

I wonder about your high-pressure regulator. I looked up the MM Pro 1000mm, and saw pictures of a rather ordinary-looking low pressure (11 inWC) regulator,

and compared it to the standard propane grill units used on the consumer Mosquito Magnets:

Except for the color, these look basically the same to me. Also, the MM Pro 1000mm product description says that the unit runs for about 21 days on a 20# tank, the same as the other models that use standard a low pressure regulator.

Running a copper line from the regulator directly to the nozzle didn't change the operating temperature

Perhaps the propane flow is way too high. This would cause too-low temperatures. Do you smell propane in the exhaust?

Regarding your picture, I don't understand the "air mixture screw." There appear to be two cylinders in the photo, one vertical, and one horizontal with copper lines on both sides. What is that device? Could it be a (clogged) fuel filter? I see what could be a screw coming out of the bottom of the horizontal cylinder. If it is a screw, perhaps it constricts the gas flow, and adjusts the rate of propane going into the chamber, much like the tiny holes in a nozzle. Because the air flow is fixed, this would adjust the mixture. When you said you bypassed the

I hope you didn't mean the screw-like thing that looks like a fitting coming out the bottom of the vertical unit (the burner?), I have no idea what that is. I guess I need another photo.

On another matter, I saw a troubleshooting page that recommended periodically shaking the unit to redistribute the catalyst beads. It also has a nice picture suggesting a proper bead quantity.

I'm really glad that we don't have to shake our consumer units (although my 1 year old Patriot has just stopped working, I guess I actually would like to shake it).

|

Re: Temperature Too Low August 03, 2020 07:21PM | Registered: 3 years ago Posts: 8 |

I think biofuelin meant to say "10-12 inches of water column" rather than PSI.

Regarding the pressures, refer to patent 6,145,243 column 6, number 40. "In operation, gas flows from tank 14 through the tanks shut-off valve and flexible line 22 to regulator 24, which drops the gas pressure to 15 psi. The gas continues at 15 psi to the input side of safety valve 58, which is a flame sensing type of valve."

This 15 psi does seem high, however it does go on further to say "Immediately after passing through filter 112, the gas escapes to atmospheric pressure through restrictor 113, which has a 0.004 inch diameter orifice. The gas flows through restrictor 113 as a rate of about one pound of propane in 36 hours."

That rate seems correct, so presumably the 15 PSI/.004 orifice combination is more or less equivalent to the 11" WC/Delavan nozzle combo in the other units. If I read the Delevan specs correctly (not 100% sure because their part numbers seem to have changed) the 015-45A nozzle has an orifice diameter of about .013". If this is true, the Delavan has >10X the area of the MM1000, so it makes sense they are operating at different pressures.

In the pic, the vertical cylinder is the "carburetor" and that screw thing coming out of the bottom is the adjustment. It protrudes into the hole in the side of the cylinder.

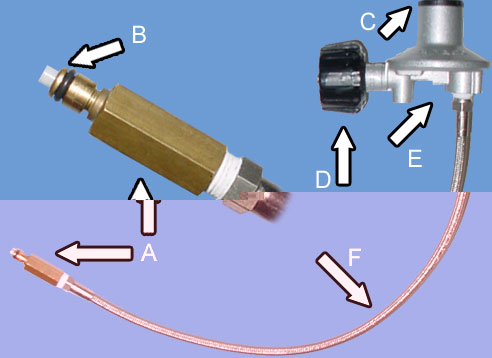

Attached are pics of the nozzle and the venturi from my MM1000. I don't suppose the spider living in there helped the gas flow any :) But you can see this is quite a different animal from the Defender/Liberty series. I can't totally make out the writing on the nozzle.

Edited 1 time(s). Last edit at 08/05/2020 02:58AM by Ziggy.

Regarding the pressures, refer to patent 6,145,243 column 6, number 40. "In operation, gas flows from tank 14 through the tanks shut-off valve and flexible line 22 to regulator 24, which drops the gas pressure to 15 psi. The gas continues at 15 psi to the input side of safety valve 58, which is a flame sensing type of valve."

This 15 psi does seem high, however it does go on further to say "Immediately after passing through filter 112, the gas escapes to atmospheric pressure through restrictor 113, which has a 0.004 inch diameter orifice. The gas flows through restrictor 113 as a rate of about one pound of propane in 36 hours."

That rate seems correct, so presumably the 15 PSI/.004 orifice combination is more or less equivalent to the 11" WC/Delavan nozzle combo in the other units. If I read the Delevan specs correctly (not 100% sure because their part numbers seem to have changed) the 015-45A nozzle has an orifice diameter of about .013". If this is true, the Delavan has >10X the area of the MM1000, so it makes sense they are operating at different pressures.

In the pic, the vertical cylinder is the "carburetor" and that screw thing coming out of the bottom is the adjustment. It protrudes into the hole in the side of the cylinder.

Attached are pics of the nozzle and the venturi from my MM1000. I don't suppose the spider living in there helped the gas flow any :) But you can see this is quite a different animal from the Defender/Liberty series. I can't totally make out the writing on the nozzle.

Edited 1 time(s). Last edit at 08/05/2020 02:58AM by Ziggy.

|

Re: MM Pro 1000mm June 17, 2021 12:54AM | Registered: 2 years ago Posts: 19 |

Hi, folks. Brand new here, so please bear with me as I ask some (inevitably) stupid questions.

I'm just getting into these things - got a Defender last fall and a Pro more recently. The Defender seems to have

just come up without any fuss, though it hasn't yet caught a single bug. At this stage my best guess is that the octenol

cartridges I got with it were badly stored (the boxes are faded) and NFG. New ones en route.

The Pro, though, came without a regulator or hose. So my first question is: Without my descending into reading and

getting up to speed with a lot of history, is there a FAQ version of where I can best (meaning cheap without sacrificing

quality) source an adjustable regulator, and once I've done so, what pressure it needs to be set to?

For background, I'm a longtime embedded systems (hardware) engineer, so I'm pretty comfortable with everything I've

seen discussed here via casual browsing. And I'm rural, so pretty self-sufficient, meaning I have useful things like

digital manometers kicking around.

Much appreciated, and looking forward to some interesting exchanges.

I'm just getting into these things - got a Defender last fall and a Pro more recently. The Defender seems to have

just come up without any fuss, though it hasn't yet caught a single bug. At this stage my best guess is that the octenol

cartridges I got with it were badly stored (the boxes are faded) and NFG. New ones en route.

The Pro, though, came without a regulator or hose. So my first question is: Without my descending into reading and

getting up to speed with a lot of history, is there a FAQ version of where I can best (meaning cheap without sacrificing

quality) source an adjustable regulator, and once I've done so, what pressure it needs to be set to?

For background, I'm a longtime embedded systems (hardware) engineer, so I'm pretty comfortable with everything I've

seen discussed here via casual browsing. And I'm rural, so pretty self-sufficient, meaning I have useful things like

digital manometers kicking around.

Much appreciated, and looking forward to some interesting exchanges.

|

Regulator for Pro June 17, 2021 01:16PM | Admin Registered: 7 years ago Posts: 164 |

Welcome to the forum, where the only stupid question is the one you didn't ask (is there a better way to put this?).

If it were not the Pro, you would use a regular garden variety fixed regulator, which has a fixed 11 inWC. My 2002 Defender used a regulator with an cap that unscrewed to reveal an adjustment, but modern regulators don't have this. In 2019, I searched for a low pressure adjustable regulator without success (there might have been one, but it looked iffy for other reasons). The only adjustable regulators were high pressure, which would not be accurate enough at the very low pressures used for gas grills.

I vaguely remember looking at pictures of regulators attached to traps to see if and when MM changed to a fixed regulator. One of the pictures was of a Pro or Pro-like trap. I remember being a bit surprised to see the same-looking regulator. Edit: Silly me, this picture is in one of my previous messages above.

There are a few things to remember. First, the amount of propane used is the flow rate times the time.How long does the 20# tank last in the Pro? For the other traps, it is about 21 days. The trap lasts 21 days on a 20# tank. Second, the flow rate is proportional to the pressure times the inverse restriction, which comes from the nozzle (clean the nozzle). If the Pro uses more propane, it might be because of the nozzle. Disassemble, clean, and look up the nozzle specs (and post them here...).

For a discussion of some of this, see the blog.

Regarding your octenol, does it have that 'yummy,' octenol fragrance? If so, it is probably OK.

You might have a nozzle or regulator issue with the Defender. See the blog. Your manometer might work. You could also build a wireless pressure gauge as in the blog to measure the pressure via the Schrader valve (a regular gauge won't work because the pressure is so low.)

Edited 1 time(s). Last edit at 06/17/2021 05:04PM by dev.

If it were not the Pro, you would use a regular garden variety fixed regulator, which has a fixed 11 inWC. My 2002 Defender used a regulator with an cap that unscrewed to reveal an adjustment, but modern regulators don't have this. In 2019, I searched for a low pressure adjustable regulator without success (there might have been one, but it looked iffy for other reasons). The only adjustable regulators were high pressure, which would not be accurate enough at the very low pressures used for gas grills.

I vaguely remember looking at pictures of regulators attached to traps to see if and when MM changed to a fixed regulator. One of the pictures was of a Pro or Pro-like trap. I remember being a bit surprised to see the same-looking regulator. Edit: Silly me, this picture is in one of my previous messages above.

There are a few things to remember. First, the amount of propane used is the flow rate times the time.

For a discussion of some of this, see the blog.

Regarding your octenol, does it have that 'yummy,' octenol fragrance? If so, it is probably OK.

You might have a nozzle or regulator issue with the Defender. See the blog. Your manometer might work. You could also build a wireless pressure gauge as in the blog to measure the pressure via the Schrader valve (a regular gauge won't work because the pressure is so low.)

Edited 1 time(s). Last edit at 06/17/2021 05:04PM by dev.

|

Re: Welcome debugger June 18, 2021 07:05AM | Registered: 3 years ago Posts: 5 |

Welcome Debugger! This is a great forum with a wealth of knowledge and awesome people willing to share it.

For a cheap Pro series regulator, check ebay or if you are ever around metro Detroit, I have extra used regulators with proper hose.

Like Dev described about his defender, the Pro series regulators are similarly adjustable. Unlike the other models, the Pro should be set around 10 psi. I have tried a number of overpriced regulators, but the OEM Pro series regulators are pretty dependable. Once you get your machine operating, you can fine tune the pressure.

Good luck

For a cheap Pro series regulator, check ebay or if you are ever around metro Detroit, I have extra used regulators with proper hose.

Like Dev described about his defender, the Pro series regulators are similarly adjustable. Unlike the other models, the Pro should be set around 10 psi. I have tried a number of overpriced regulators, but the OEM Pro series regulators are pretty dependable. Once you get your machine operating, you can fine tune the pressure.

Good luck

|

10 psi, wow June 18, 2021 03:09PM | Admin Registered: 7 years ago Posts: 164 |

Quote

Unlike the other models, the Pro should be set around 10 psi.

10 psi? Wow! Is there another regulator inside? Is the nozzle very fine? What about that picture I found last year, showing a more or less garden variety regulator on the Pro? If that is incorrect, I should correct my post. And a wiki page might be helpful.

|

Re: Welcome debugger June 18, 2021 03:56PM | Registered: 2 years ago Posts: 19 |

biofuelin Wrote:

-------------------------------------------------------

> For a cheap Pro series regulator, check ebay or if you are ever around

> metro Detroit, I have extra used regulators with proper hose.

...

> I have tried a number of overpriced regulators, but the OEM Pro series

> regulators are pretty dependable. Once you get your machine operating,

> you can fine tune the pressure.

Thanks. Can you be a little more specific on this? By "OEM" do you actually

mean MM-branded product? Because I don't think they support this dinosaur

anymore. An ebay search turns up hundreds of adjustable regulators of the

"big red knob" style, and I'd rather prefer one like the Defender type, with a

screwdriver adjustment under a cap to avoid accidental changes.

Unfortunately, I don't often find myself around Motor City - I'm across the

continent and over the border. But I'd still be interested in taking you up on

your offer of a used one if you don't mind dropping it in the mail. If so, please

PM me.

-------------------------------------------------------

> For a cheap Pro series regulator, check ebay or if you are ever around

> metro Detroit, I have extra used regulators with proper hose.

...

> I have tried a number of overpriced regulators, but the OEM Pro series

> regulators are pretty dependable. Once you get your machine operating,

> you can fine tune the pressure.

Thanks. Can you be a little more specific on this? By "OEM" do you actually

mean MM-branded product? Because I don't think they support this dinosaur

anymore. An ebay search turns up hundreds of adjustable regulators of the

"big red knob" style, and I'd rather prefer one like the Defender type, with a

screwdriver adjustment under a cap to avoid accidental changes.

Unfortunately, I don't often find myself around Motor City - I'm across the

continent and over the border. But I'd still be interested in taking you up on

your offer of a used one if you don't mind dropping it in the mail. If so, please

PM me.

Sorry, only registered users may post in this forum.